A Guide for Eye Bolts and Lifting Points - Types and Safe Use.

1. Overview

To download this information as a PDF CLICK HERE

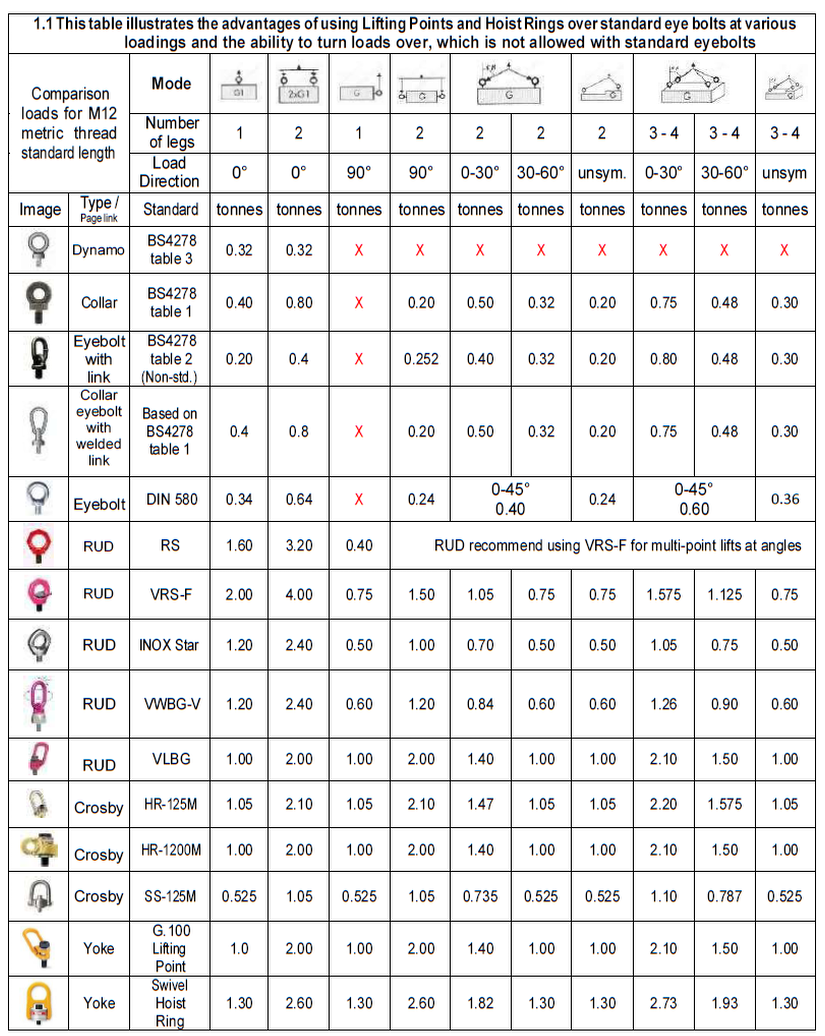

Eyebolts, one of the most commonly used items of lifting gear, have severe limitations in usage and a high level of accidents occur as the result of misuse. Eyebolts are used in a wide variety of applications to provide lifting points on loads. Sometimes the hole they are screwed into is there specifically for the eyebolt.

Alternatively, a hole which is primarily intended for some other purpose, such as a stud, can be utilised. Traditionally eye bolts were often fitted to their load and left in place for life, is regarded as part of the load. However, the modern practice is to treat detachable lifting points as lifting accessories. As such most countries require that they are periodically inspected or thoroughly examined. Therefore good practice is to remove eyebolts, plug the holes and put the eyebolts into storage until needed. This often considerably reduces the quantity required and opens up other options.

In general, the best alternative to eyebolts are the modern lifting points, swivel links, and hoist rings. Although there is not a specific standard for these, several reputable manufacturers including Codipro, Crosby, RUD, and Yoke, who make them to their own designs. These new generation lifting points offer advanced engineering and increased load capacities over standard eyebolts.

These new links are considerably more expensive than traditional eyebolts but their advantages can easily outweigh their initial cost which is, in any case, often low compared to the value of the machinery they are to lift. The table below shows the benefits of strength and usability.

2. Eye Bolt Types

Dynamo Eyebolts 2.1

They are designed for axial loading only, for example, along the axis of the screw thread. They usually have a small diameter collar between the eye and the screw thread.

However, this is not sufficient to support the eye if it is loaded at an angle to the thread axis. They are called dynamo eyebolts, which reflects their original application in early power generators.

Prior to the introduction of a British Standard, dynamo eyebolts were manufactured to a wide range of ‘commercial’ patterns of varying quality. However, their typical applications were such that they were usually only used a few times during the lifetime of the equipment they were screwed into. As such cost was a more important consideration than performance characteristics like fatigue life.

Dynamo Eyebolts - For Axial loads only (NOT TO BE USED FOR ANGLED LIFTS)

- Material: B S970-080A27 hardened and tempered

- Safety Factor: MBL equals 5 x SWL

- Standard: B.S. 4278 - table 3 - 1984

- Finish: self-colour, electro-galvanized

- Certificates: this product is supplied with a works certificate as standard

- Note : upon request a basic raw material and/or EC Declaration of Conformity is available

Dynamo eyebolts are available in (Click on type required to view more)

- Metric coarse thread Standard shank Self-colour

- Metric coarse thread Standard shank Zinc Plated

- Metric coarse thread long shank Self Colour

- Metric coarse thread long shank Zinc plated

- BSWThread standard shank Self-Colour

- BSWThread standard shank Zinc plated

- BSW Thread long shank Self-colour

- BSW Thread long shank Zinc Plated

Collared Eyebolts 2.2

The answer is an eyebolt with a large collar between the eye and the screw thread. With the collar screwed firmly down onto a machined face, it can support the eye and prevent any bending of the screw thread.

By also reducing the size of the eye, it keeps the leverage to a minimum. This design is called a collar eyebolt and can be considered as the general-purpose eyebolt.

The underside of a collar eyebolt has a thread run-out at the top of the screw thread and an undercut of the collar. Small radius curves blend the transitions between the screw thread, plain shank, undercut and collar. These avoid unnecessary stress concentrations which can lead to fatigue failure and the undercut ensures that the collar can sit fully down onto a machined face.

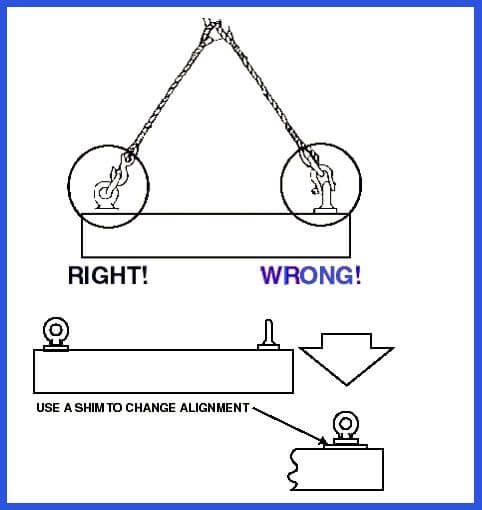

Although a collar eyebolt is designed for angular use it is nevertheless necessary to align the eye to the line of pull. A tolerance of ±5º is acceptable but it is a matter of luck whether this will be achieved when first screwed in because the eyebolt manufacturer has no control over the start point of the threaded hole. Therefore it is permissible to shim up to half the screw pitch to achieve the correct orientation.

This brings us to some details about the screw thread itself. The current British Standard for eyebolts is BS 4278 and it specifies coarse series metric threads. Eyebolts are made from higher tensile steel and, if screwed into the same strength material, would need only to engage for a length equal to that of a full nut. However, it is possible and even likely that the material they are screwed into will be considerably weaker. The screwed length is therefore extended to compensate. Also, the eyebolt manufacturer has no control over the tolerances of the screwed hole, hence the restriction to coarse series threads.

The screw thread required for a particular application is of course dictated by the threaded hole. New eyebolts are required to fit old equipment which may have imperial threads. Standard eyebolts can have other screw threads and BS 4278 does allow for imperial threads for replacement purposes.

A final point for the user to check is that the thread forms of the eyebolt and hole are the same. Unfortunately, certain sizes of metric, UNC and Whitworth threads will engage with each other and appear to be compatible.

However, they are, in effect, hanging on by their fingertips and not strong enough to take the load. When the current British Standard was written, an exercise was carried out to identify these possible mismatches and they were eliminated from the standard range of sizes.

Unfortunately, the standard cannot control this problem entirely and certainly not when special sizes and thread forms are specified.

Stresses

When used at an angle, the working load of a collar eyebolt must be reduced to take account of the different stresses imposed. For the BS 4278 collar eyebolt, the reduction factors are: 0.63 for angles up to 15º to the vertical; 0.4 for angles up to 30º; 0.25 for angles up to 45º. These reductions are considerably more than those which apply to slings.

The logic behind them is that the force on an eyebolt increase due to two factors: the geometry as in a sling, and the additional effect of loading it at an angle to its axis. These reduction factors are now being challenged by a new standard which has just been approved jointly by ISO and CEN.

Whereas the current British Standard is fully dimensioned, the new standard is a performance standard with a limited dimensional envelope for compatibility purposes only. It allows manufacturers to design eyebolts capable of working to the same angle factors as used for slings.

As this standard is very new and not yet implemented into national standards, it remains to be seen how many manufacturers will take advantage of it. It is hoped many do as it is a significant step forward.

Meanwhile, for the foreseeable future, products to the current standard are likely to be the most widely available.

Collared Eyebolts

- Material: BS970-080A27 hardened and tempered

- Safety Factor: MBL equals 5 x SWL

- Standard: B.S. 4278 - table 1 - 1984

- Finish: self-colour, electro-galvanized

- Certificates: this product is supplied with a works certificate as standard

- Note: upon request a basic raw material and/or EC Declaration of Conformity is available

Collared eyebolts are available in (Click on type required to view more)

-

COLLARED EYEBOLTS - METRIC ( BS4278 - TABLE 1 - 1984 ) - SELF COLOUR

-

COLLARED EYEBOLTS - METRIC ( BS4278 - TABLE 1 - 1984 ) - ZINC PLATED

-

COLLARED EYEBOLTS - BSW THREAD (BS4278 - TABLE 4 - 1984 ) - SELF COLOUR

-

COLLARED EYEBOLTS - BSW THREAD (BS4278 - TABLE 4 - 1984 ) - ZINC PLATED

-

COLLARED EYEBOLTS - UNC THREAD (BS4278 - TABLE 4 - 1984 ) - SELF COLOUR

-

COLLARED EYEBOLTS - UNC THREAD (BS4278 - TABLE 4 - 1984 ) - ZINC PLATED

Eyebolts with Link 2.3

The origin of this eyebolt is the swivels which were once widely used in traditional ships’ derrick rigs. One of the two forgings used to make the swivel is, in effect, a very compact form of collar eyebolt. The eye is just large enough to accept a link of comparable grade and strength. The link can articulate in any direction within the eye. In combination with the very compact eye, this allows it to be loaded in any direction, removing the need to align the eye to the line of pull. For a given thread size the axial working load is less than that of a collar eyebolt but the reduction

factors for angular use are better. They can be used up to 15º to the vertical without any reduction and the other factors are 0.8 for angles up to 30º and 0.63 for angles up to 45º. Unfortunately, because of their origin, they are only available in a small range of sizes.

Eyebolts With Oval Link - metric coarse thread

- Material: BS970-080A27 hardened and tempered

- Standard: B.S. 4278 - table 2 – 1984

- Safety Factor: MBL equals 5 x SWL

- Finish: self-colour

- Certificates: this product is supplied with a works certificate as standard

- Note: upon request a basic raw material and/or EC Declaration of Conformity is available

Eyebolts with links are available in (Click on type required to view more)

EYEBOLTS WITH OVAL LINK - METRIC ( BS4278 - TABLE 2 - 1984 )

Collar Eyebolt with Welded Link 2.4

However, they should not be confused with the standard eyebolt with a link. Their rating and the alignment requirements are still those of a collar eyebolt.

- Material:: Eyebolt: BS970-080A27 hardened and tempered.: Link:: high tensile steel

- Safety Factor MBL equals 5 x SWL

- Finish: self-colour

- Certificate: this product is supplied with a works certificate as standard

Note: for safe working load when used at angles please refer to safety instructions.

For eyebolt, dimensions refer to BS 4278 tables 1 & 4

Eyebolts with links are available in (Click on type required to view more)

COLLARED EYEBOLTS C/W REEVABLE EGG LINK - METRIC

COLLARED EYEBOLTS C/W REEVABLE EGG LINK - BSW THREAD

Eyebolts to DIN 580 2.5

Eyebolts to DIN 580 are available in (Click on type required to view more)

EYEBOLTS - METRIC COARSE THREAD TO DIN 580 - SELF COLOUR FINISH

EYEBOLTS - METRIC COARSE THREAD TO DIN 580 -ZINC PLATED FINISH

Stainless Steel Lifting Eyebolts - DIN 580

Female Eye Nuts and Bow Nuts 2.6

The standard specified mild steel although other grades may be commercially available. It would be better to avoid using them, although it is acknowledged that there may be applications where there is no better alternative. If they are used, they should only be loaded axially and clearly the stud they are screwed onto is a critical component in the connection. For angular loadings see RUD VRM

High Tensile Steel Normalised Eye Nuts 2.7

Axial loads only (NOT TO BE USED FOR ANGLED LIFTS

Eyenuts - metric coarse ( BSW thread available)

• Material: high tensile steel

• Safety Factor: MBL equals 5 x SWL

• Finish: self colour, electro-galvanised upon request

• Certificates: this product is supplied with a works certificate as standard

Eye nuts are available in (Click on type required to view more)

Eyenuts - metric coarse thread - Self Colour

Eyenuts - metric coarse thread - Zinc Plated

Eyenuts - BSW thread - Self Colour

Eyenuts - BSW thread - Zinc Plated

High Tensile Steel Normalised Bow Nuts 2.8

For Axial loads only (NOT TO BE USED FOR ANGLED LIFTS)

Bownuts - metric coarse ( BSW thread available)

• Material: high tensile steel

• Safety Factor: MBL equals 5 x SWL

• Standard: generally to B.S. 3974 - Part 1 - 1974

• Finish: self-colour, electro-galvanised upon request

• Certificates: this product is supplied with a works certificate as standard

Bow nuts are available in (Click on type required to view more)

Bownuts - Metric coarse thread - Self Colour

Bownuts - Metric coarse thread - Zinc Plated

Bownuts - BSW thread - Self Colour

Bownuts - BSW thread - Zinc Plated

Eye Nuts to DIN 582 2.9

here are also DIN582 (Foreign) standard eye nuts with the same properties and angle reductions as DIN 580 Eyebolts. Material identification symbol: C15 or C15E.

• Material: carbon steel, C15

• Safety factor: MBL equals 4 x WLL

• Standard: generally to DIN 582

• Finish: self-colour or electro-galvanised

• Certification: This product is supplied with a works certificate as standard

Eye nuts to DIN 582 are available in (Click on type required to view more)

EYENUTS - METRIC COARSE THREAD TO DIN 582 - SELF COLOUR

EYENUTS - METRIC COARSE THREAD TO DIN 582 - ZINC PLATED

Stainless Steel Lifting Eyenuts - DIN 582

RUD RS EYEBOLTS 2.10

Forged, tempered and 100% crack detected.

Fool-proof compared with common DIN eye bolts by:

- Shape: Octagonal means quality class 8

- Identification: Distinct indication of WLL for the most unfavourable case (lateral load - not allowed with DIN 580).

- Ensure the eye bolt is bolted down flush to the surface! Avoid twisting movements during transport.

- Complies with the machinery directives 2006/42/EG

Also available in imperial and special threads.

Before lifting check the tightness of the eye bolt

and nut!

▲Avoid rotating movement during transport.

Assure a plane bolting surface.

Attention: Refer to RUD user instructions!

RUD RS Eye bolts are available in (Click on type required to view more)

RUD RS Eye Bolt - Metric Thread

RUD RS Eye Bolt - UNC / UN Thread

RUD RM Eye Nut

RUD RM Eye Nuts are also available

Higher WLL than compared with DIN 582 eye nuts.

Forged, tempered and 100% crack detected. Fool-proof compared with common DIN eye nuts

by:Shape: Octagonal means quality class 8 Identification: Distinct indication of WLL for the most

unfavourable case (lateral load - not allowed with DIN 582).In order to guarantee the WLL, the

thread connection must at least consist of quality 8.8. Eyenut must be bolted tight during use. Avoid

twisting movements during transport.

■ The given WLL is only valid in connection with threaded bolts of at least quality class 10.9.

RUD RM Eye nuts are available in (Click on type required to view more)

RUD RM Eye Nut - Metric Thread

RUD STARPOINT VRS -F EYEBOLTS 2.11 Vario-Starpoint VRS with star key

Colour: striking fluorescent pink powder coating.

Identification: Clear WLL 90°indication for the most unfavourable load direction (not permissible for DIN 580).

Forged material 1.6541, high tensile and annealed, 100% electromagnetic crack detected according to EN 1677-1 and with a 4 :1 design factor.

If the VRS permanently to remain at the point of force introduction, it must be tightened with a torque of 5 Nm.

Complies with the machinery directives 2006/42/EG

RUD VRS Starpoint Eye bolts are available in (Click on type required to view more)

RUD VRS-F STARPOINT - Metric Thread

VRS-F STARPOINT, UNC/UN thread

RUD VRM STARPOINT ( Eye Nut ) - Metric Thread 2.11 Continued

- The body of the STARPOINT nut must be turnable 360° in bolted condition. Adjust in pull direction before attaching the sling means.

- A plane bolting surface has to be assured. The nut thread must be engaged to 100 % with the bolt thread. The threaded pin mounted must allow a perfect seat of the surface of the eye nut to the bolting surface.

- Sizes of VRM - see drawing VRS-StarPoint. Size „L“ corresponds with the minimum length of the bolt thread.

- In case of flipping fixtures dies and moulds, under full load, we recommend using our double ball-bearing powerpoint collection.

- The given WLL for 90° is only valid in connection with threaded bolts of at least quality class 10.9.

RUD VRM Starpoint Eye nuts are available in (Click on type required to view more)

RUD VRM STARPOINT ( Eye Nut ) - Metric Thread

RUD INOX STAR Eyebolt 2.12

- Pentagonal shape – significantly different from the DIN 580 eyebolt.

- Turns through 360°. Can be set in the direction of the load.

- A clear statement of rated load 90°for the unfavourable load range. Safety factor 4: 1.

- Forged eye body.

- The material of eye body and screw: 1.4462, duplex steel (high durability in seawater and in environments with high chlorine ion concentrations).

- 100 % crack-tested

- Captive mounted bolt.

- Patented wear marks on the eye body.

- Tighten hand-tight when mounting with a hexagonal wrench or adapter piece. Do not use an extension.

- The INOX-STAR must be able to be turned through 360° when screwed in.

- Set in the direction of force before loading.

- Component protected under patent law: European patent EP 654611.

RUD INOX Starpoint Eyebolts are available in (Click on type required to view more)

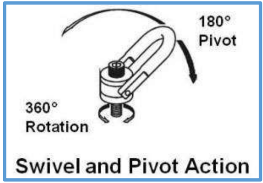

RUD VWBG-V– 360° swivelling/180° pivoting Lifting Points 2.13

- Swivelling lifting point:

- Loadable in any direction. Safety factor 4: 1.

- Turnable under load in the vertical direction.

- Not suitable for permanent swivelling under full load, especially in 90° direction.

- Simple installation, just a thread hole is required.

- Variable lengths (Vario) available.

- Can also be used for through holes.

- Bolts 100 % magnetic crack detected! Surface protection CORRUD-DT (20 times better than zinc plating).

- High tensile, approved suspension ring acc. EN 1677-4.

- Surface: Ring pink powder coating, housing zinc plated.

- Type Vario with washer and 100 % crack detected nut.

- VWBG-V and VWBG are also available with Imperial thread.

- Turning without jerk due to additional bush bearing washer.

- Wear marks in the main load directions 45°, 60° and 90°.

RUD VWBG-V are available in (Click on type required to view more)

RUD VWBG Load Ring - Metric Thread

RUD VWBG Load Ring - Metric Thread with Variable Length

VWBG-V Load Ring - UNC Thread With Variable Length

RUD VLBG Load Ring 2.14

RUD VLBG Load Ring 2.14

- VLBG Load Ring will turn 360°, adjustable in pull direction.

- Load ring foldable, full WLL in any load direction, surface pink powder coated.

- The max. lengths of the RUD - bolts are adjusted in such a way that if a hex-head-shaped nut (DIN EN ISO 7042) is used,

- Assemblies of material thickness of approximately 8 *M (for M8 - M30) and 5 *M for (M36 - M48) can be realised respectively.

- In case of flipping fixtures dies and molds, under full load 90°,

- We recommend to use our double ball bearing power point collection

- Complies with the machinery directives 2006/42/EG

RUD VLBG are available in (Click on type required to view more)

RUD VLBG PLUS Load Ring - Metric Thread

RUD VLBG PLUS Max Length Load Ring - Metric Thread

CROSBY HR125M - SWIVEL HOIST RING - METRIC 2.15

CROSBY HR125M - SWIVEL HOIST RING - METRIC 2.15

• Metric threads available in sizes from 400kg to 16,900kg and dual rated in both a 4 to 1 and 5 to 1 design factor.

• All Components are Alloy Steel - Quenched and Tempered.

• Rated at 100% at 90° angle.

• 100% individually proof tested to 2-1/2 times the Working Load Limit with certification and Statistically Magnetic Particle inspected.

• 360° swivel and 180° pivot action.

• Bolt is secured with E-clip, threads are grooved. This method allows for easy disassembly and assembly of hoist ring for thorough examination of all components. Replacement kits are available. • Bolts are individually Proof Tested.

• Multiple Bolt length available to meet specific application requirements.

• Zinc Plated (Yellow Chromate) finish for increased corrosion protection

CROSBY HR125M are available in (Click on type required to view more)

CROSBY HR125M - SWIVEL HOIST RING - METRIC

Also available in stainless steel

CROSBY SS125M - STAINLESS STEEL SWIVEL HOIST RINGS - METRIC

CROSBY HR-1200M Metric - Side Pull Hoist Rings 2.16

CROSBY HR-1200M Metric - Side Pull Hoist Rings 2.16

• Wide range of capacities available: Also available with UNC thread.

• Metric sizes from 300 kg. to 13.000 kg.

• Body components are Alloy Steel - Quenched and Tempered.

• Rated at 100% of Working Load Limit for angles up to 90 degrees.

• Each product is stamped with a Product Identification Code (PIC), for material traceability, along with a Working Load Limit, and the name Crosby or “CG”.

• Utilize standard Crosby Red Pin® Shackles to connect to wire rope or synthetic slings. (sold separately)

• Multiple bolt lengths available to meet specific application requirements.

• All sizes are RFID EQUIPPED

CROSBY HR-1200 are available in (Click on type required to view more)

CROSBY HR-1200M Metric - Side Pull Hoist Rings

CROSBY HR1200 - SIDE PULL SWIVEL HOIST RING - UNC

YOKE Grade 100 Swivel Lifting Point Metric Thread 2.17

YOKE Grade 100 Swivel Lifting Point Metric Thread 2.17

• Grade 100 Lifting Points are 360degrotation with a 90deg pivot function

• Bolts are metric thread (ASME/ANSI B18.3.1M), specification is a grade 10.9 alloy socket head screw per DIN EN ISO 4762

• Proof Load individually to 2.5 times Working Load Limit and certified

• Rated at 100% at 90deg angle

• 100% magnaflux crack detection

• Long shank bolts available on request

• Also in UNC thread

YOKE Grade 100 Swivel Lifting Points are available in (Click on type required to view more)

YOKE G10 Swivel Lifting Point/Ring Metric Thread

YOKE G10 Swivel Lifting Point/Ring UNC Thread

Yoke Swivel Hoist Ring with metric thread 2.18

Yoke Swivel Hoist Ring with metric thread 2.18

• Yoke Hoist Rings will turn 360° and pivot 180° allowing the adjustment in pull direction

• Yoke Hoist Rings retain 100% of the rated capacity @ 90°

• Extended shank length available on request

Yoke Swivel Hoist Rings are available in (Click on type required to view more)

Yoke Swivel Hoist Ring with metric thread

Yoke Swivel Hoist Ring with UNC thread

3.Manufacturers

RUD

RUD lifting point parts are either 100% crack detected and proof loaded according to EN 1677. and are in accordance with DIN EN 818 and 1677. 360° adjustable in pull direction. Load ring foldable, Marked with full 100% WLL in any load direction. Safety factor 4:1.

CODIPRO

Codipro Eye Bolts and Swivel Rings

Manufactured according to the EN 1677-1 standard

CROSBY

Crosby hoists rings are rated at 100% at 90° angle. 100% individually proof tested. WLL and the name Crosby or “CG” stamped into it. Meets or exceeds all the requirements of ASME B30.26 (US) 360° swivel and 180° pivot action.

YOKE

All YOKE G-100 Lifting Point meet or exceed all the requirement of ASME B30.26 Each forged parts and cap screw with Batch code links to Test Certificate. G-100 Lifting Point Bail are designed by forged alloy steel, quenched and tempered. G-100 Lifting Point are 360° rotation with 90° pivot function.

4.Safe Use and Maintenance

Inspection

In the UK, the Lifting Operations & Lifting Equipment Regulations (LOLER) make it clear that all eyebolts and indeed shackles (See our information specifically on shackles) used for lifting purposes are lifting accessories. They should therefore be subject to a thorough examination by a competent person at least every six months. Regardless of the prevailing legislation, the Lifting Equipment Engineers Association (LEEA) strongly recommends that this policy is adopted by all those with responsibility for ensuring the safe condition of lifting equipment.

Safe Use and Maintenance

• Loads may slip or fall if proper eyebolt assembly and lifting procedures are not used. A falling load can cause serious injury or kill.

• Follow all eyebolt safety information supplied. Always inspect eyebolt before use.

• It should be marked with a Working Load Limit valid for in-line pull, thread diameter, material identification symbol, manufacturer’s symbol and CE mark.

• Make sure all markings are legible. Unmarked eyebolts should be immediately removed from use

• Never use eye bolt that shows signs of wear, nicks, gouges or cracks.

• Never use eyebolt if eye or shank is bent or elongated.

• Always be sure threads on shank and receiving holes are clean.

• Never repair or reshape an eye bolt or eye nut by welding, heating or bending as this may affect the Working Load Limit;

• Never machine, grind, or cut an eyebolt. Never exceed load limits specified. Never use dynamo eyebolts for angular lifts. Always use collar eyebolts (or machinery eyebolts) for angular lifts.

• Never undercut an eye bolt to seat shoulder against the load.

• Always countersink receiving hole or use washers to seat shoulder. Always screw eyebolt down completely for proper seating.

• Always tighten nuts securely against the load. When using collar eyebolts for angular lifts, please refer to the standards for eyebolts BS4278 & DIN 580, or DIN 582 for eye nuts.

• It is required that the products are regularly inspected and that the inspection should take place in accordance with the safety standards given in the country of use. This is required because the products in use may be affected by wear, misuse, overloading etc. with a consequence of deformation and alteration of the material structure.

• Inspection should take place at least every six months and even more frequently when the products are used in severe operating conditions.

• Read, understand and follow the information in diagrams and charts relevant to eyebolt types before use. If in doubt seek expert advice - Do Not Attempt Lift.

Storage

Eyebolts need to be stored correctly to prolong usability. It is accepted practice to wrap threads in insulating tape or similar. However, it may better to obtain matching nuts which will protect the thread end and when given a few turns will assure the rigger or inspector that the thread is in good condition and ready for use.

Our experience with customers tackle storage facilities is in the extreme. A gold star goes to one tackle storekeeper who carefully wrapped the threads, strung them in sets hung on a board which was clearly marked with thread type, WLL and the inspection period colour code information. We would suggest a P45 for another storeman who chucked all his eyebolts into an open metal box. Which, obviously damaged the threads and made them extremely difficult to find. But, to cap that, as the tackle store shed roof leaked and the eyebolts at the bottom of the box were underwater!

For more information please refer to the tables provided in the Lifting Eyebolts, Eye nuts and Bolted Load Rings section of this website.

Instructions for the safe use of: Eyebolts

For further advice contact our sales team on: 0161 223 1990 or by email: mail to: sales@dalelifting.co.uk

RUD VLBG Load Ring 2.14

RUD VLBG Load Ring 2.14 CROSBY HR125M - SWIVEL HOIST RING - METRIC 2.15

CROSBY HR125M - SWIVEL HOIST RING - METRIC 2.15 CROSBY HR-1200M Metric - Side Pull Hoist Rings 2.16

CROSBY HR-1200M Metric - Side Pull Hoist Rings 2.16 YOKE Grade 100 Swivel Lifting Point Metric Thread 2.17

YOKE Grade 100 Swivel Lifting Point Metric Thread 2.17 Yoke Swivel Hoist Ring with metric thread 2.18

Yoke Swivel Hoist Ring with metric thread 2.18