Tensile Proof Load Testing

Tensile Proof Load Testing at Dale Lifting and Handling Specialist Manchester

Dale Lifting and Handling Engineering Services (DLH online) has experience in all kinds of proof testing techniques across a broad spectrum of industries

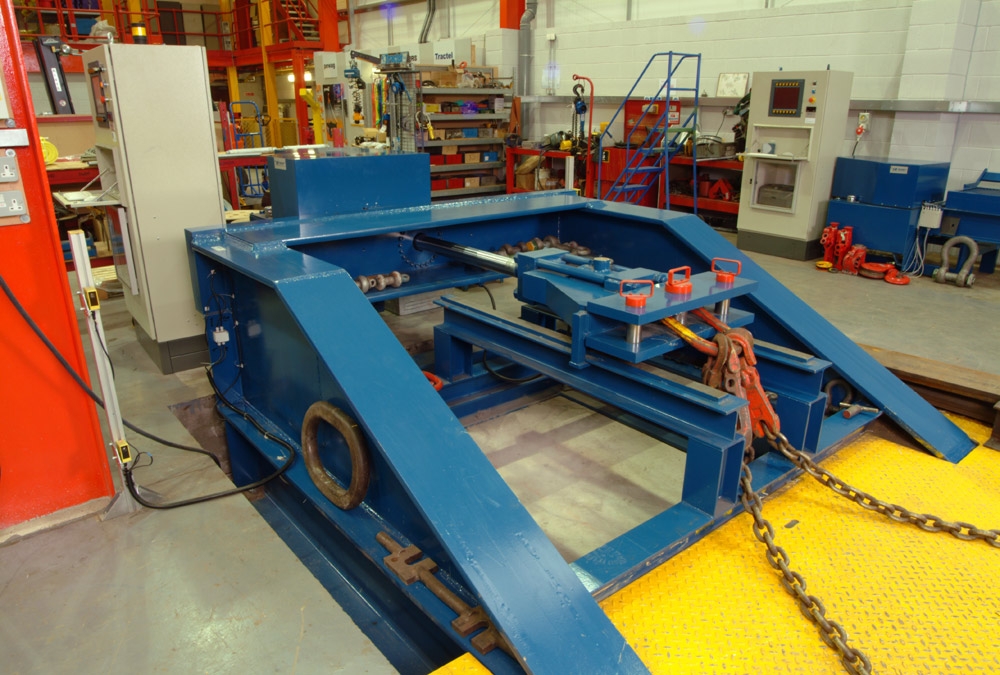

In-house testing services include: Crack detection. Proof load, stress and destruction testing are provided with an NPL certified calibrated 100 tonnes capacity computer-controlled horizontal test bed.

We can also provide 10-tonne live load and operational testing. 20 tonnes of test weights, stillages and beams. Various NPL certified calibrated digital tensile dynamometers with read-out from 1 to 12.5 tonnes.

Contact our testing and serving department for more information.

In-House proof load testing to 100 tonne – view video below on Dales’ proof testing to clients lifting equipment, load attachments and anchor points

Why tests are required

Since 1995 all new machinery in the scope of the Machinery Directive has to be designed and constructed to meet common minimum European requirements for safety. The outward signs of compliance are CE marking on the equipment and a document (Declaration of Conformity) issued by the Responsible Person (normally the manufacturer) declaring the product's conformity. To achieve compliance the Responsible Person must undertake a conformity assessment process to meet the Directive's obligations. This includes meeting all relevant essential health and safety requirements (EHSRs) for the product, producing comprehensive user instructions, and showing how compliance has been achieved in the technical file. For certain higher risk products, the conformity assessment process will normally require the use of an independent Notified Body.

These requirements have been implemented in the UK by the Supply of Machinery (Safety) Regulations 2008, as amended by the Supply of Machinery (Safety) (Amendment) Regulations 2011. In addition to machinery, these requirements also apply to interchangeable equipment, safety components placed independently on the market, lifting accessories, chains, ropes and webbing, removable transmission devices and partly completed machinery. These regulations are enforced by the HSE in Great Britain for most industrial and professional products or local trading standards services for consumer products.

Technical reports and certificates from other organisations may also be included as well as the Declaration of Conformity or Declaration of Incorporation (for the individual items of machinery that make up an assembly).

Technical files demonstrate how machinery meets relevant essential health and safety requirements and, as such, are useful for both manufacturers and national enforcing authorities. We can supply a proof load test report, crack detection test and destruction test (If applicable) for your technical file.- Contact our team on 0161 223 1990 to discuss your testing requirements.