For use on mezzanine floors, permanent or temporary loading platforms, loading docks, high-level openings and doorways.

What are the requirements for a safety pallet gate?

The HSE Guidance Says:

' You will need to provide a continuous barrier between people and the platform edge. Thereby preventing anyone from falling through the opening' (HSE case study).

This definition excludes: installing a single or twin edge gate that swings in or out from the edge, a sliding (trombone) gate, removable bars or chains. They are dangerous to operate and can often be left open and are accidents waiting to happen!

Even with safety harnesses, it doesn't solve the problem as they only protect the wearer if they remember to put it on!

The relevant international standard is

BS EN ISO 14122-3:2016 section 7.4.2 Mezzanine Gates

The standard refers to the Safety of machinery – Permanent means of access to machinery – As pallet gates are used for pallet or load handling by either a forklift truck or overhead hoist which are machines, this standard, therefore, applies to all applications where these are used.

The requirements for a safety pallet gate are that it is designed in a manner that

- It allows the operator to place and remove the load (e.g. a pallet) without being exposed to the risk of falling.

- It allows the operator to be situated outside of any danger zone during the manual control of the gate.

- It shall not restrict the movement of the persons in the transfer zone when the inner gate is open and the gate on the floor edge is closed.

- At the transfer zone (Inner gate), the space between the platform and the lower edge of the gate shall have a height of less than 500 mm in the respective closed position.

- The manual operating force shall not exceed recommended force limits for machinery operation (See EN 1005-3:2002+A1:2008 and EN1004-2:2003+A1:2008).

- The operator shall have a clear view of the transfer zone during the manual closing operation at the control position so that the risk of entrapment is minimized.

- It is self-closing in a stable position when released using, e.g. effects of gravity,

- Crushing and shearing shall be avoided during movement, in particular during the manual closing of the gate so that the risk of entrapment is minimized.

- The vertical opening (gap) shall be less than 180 mm wide between the vertical moving parts of the gate.

- The maintenance points are accessible without risk of falling.

- A toe plate (Minimumum 100 mm high) shall be provided on the edge gate where there is a risk of falling.

- Depending on the design, the opposite (Inner) gate shall have a gap of minimum 120 mm between its lower surface and the floor level to avoid the crushing of feet.

Choosing the right pallet gate

Guardrail openings and high-level openings and doorways may vary in size and function differently; you may have to consider a specific design of a safety pallet gate for each situation - one size does not fit all!

How and where Is your pallets or load to be handled?

Most types of pallet gates on the market are an up-and-over design for standard platform loading. For other applications, you may need a different mechanism. There are generally four ways that pallets are loaded:-

- The lifting and loading of the pallet/load by a forklift through a gap in the handrail of a mezzanine floor or platform.

- The lifting and loading of the pallet/load, by an overhead hoist, through a gap in the handrail of a mezzanine floor or platform.

- The lifting and loading of the pallet/load by a forklift through a high-level opening or doorway.

- The lifting and loading of the pallet/load by overhead hoist through a high-level opening or doorway.

.Most standard up and over designs will suit method 1. plus 3.(Without doors). However, hoist loading 2. and 4. Plus door openings 3. will need a different design of pallet gate.

Your answer as to which application applies to your location is just the first decision to make. You will also need the following dimensions:-

- The maximum width x depth x height of your pallet or load.

- The width of the gap in the existing or proposed handrail or wall opening.

- The headroom available (Special low headroom models are available

- The operational depth that is available of the gate operation and, if applicable, the space required to remove the pallet. (Narrow walkways or confined spaces will need a space-saving design which allows the passageway when not in use).

- For a doorway, application download our questionnaire

- We recommend that, if possible, you have 300 mm width and depth clearance on your maximum pallet/load size.

- Choose a finish: All galvanized or safety yellow thermoplastic (Warm to touch) tube coating

For helpful tips on what’s needed, you can download our guide ‘How do I specify a pallet gate?’For more ideas, see our Mezzbarriers case studies.

If you are not sure which of our 8 models to choose,tell about your application and we will select the best option for a no-obligation quotation or contact us for expert advice on 0161 223 1990 or email: sales@dale-lifting co.uk

Installing your pallet gate

A risk assessment should be carried out before installation, to include:

- Fall protection.

- If you have to make a gap in your existing handrail it should be no more than 160 mm (80 mm per side) wider than the overall width of your chosen standard or custom size pallet gate. You can download a pdf layout showing the dimensions on our pallet gate pages.

- Drilling into the floor (Concrete) or through the floor, which will require safe access to the underside of the floor to fit nuts and washers (See FAQ section Question 3. for more details)

- No-weld assembly of components eliminates the need for hot works permits and site shutdowns to deliver a safer, quicker set-up and installation with little or no damage to the finish.

Before you commence installation ensure the area of installation is clear and all the gate sections can be accounted for:-

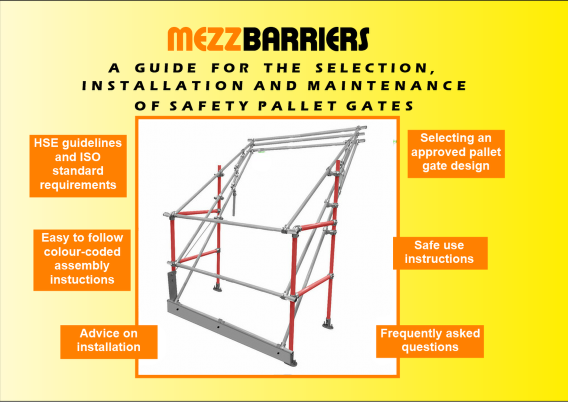

As shown your Installation and safe use instructions which are provided with all our pallet gate models

A typical instruction sheet will include the following:-

- Color-coded key sections layout for the gate showing all the main sections

- A description of each section

- Suggested method of assembly and installation

- Plus the instructions for safe use and maintenance instructions

Frequently asked questions (See more FAQ's here)

Question 1: Can you install my pallet gate?

Answer: Unfortunately no, but don’t worry, we include installation and safe use instructions.

Our pallet gates are very simple to install with just a few tools. Our pallet gates as shipped with all the main sections pre-assembled and installation usually takes about two hours for two semi-skilled operatives.

Question 2: Do you provide a pallet gate site survey?

Answer: No, but we have successfully supplied pallet gates all around the UK and as far as North America and Australia without us visiting the site. Just a few dimensions are needed. To get started download our Pallet gates at-a-glance (PDF).

Question 3: Are floor fixing bolts supplied with a pallet gate?

Answer: Floor fixing bolts are not included with the gate as floor material and thickness vary greatly. The base feet have 14 mm dia holes. You will need M12 bolt sets for wood or steel floors. For concrete floors, use anchor bolts. Thin wooden floors may need extra large washers underneath to relieve stress around the hole. Check the number of bolts required in the pdf layout, which can be downloaded on the product pages.

If the underside of a wooden floor is blocked off, you may have to use coach bolts or rubber nuts for better grip. The rubber nut for an M12 bolt will require an M24 hole. The nut is a synthetic rubber sleeve with a flange head and a threaded brass insert at the opposite end. Used in hollow base materials where the anchor can expand in the cavity.

Question 4: How long does it take to install a pallet gate?

Answer: Generally, it takes about two hours for two semi-skilled operatives to install a pallet gate on a mezzanine floor. If an existing handrail has to be removed it may take longer.

Question 5: Can you supply additional handrails for my project?

Answer: Yes, we supply ready-made posts and handrails for mezzanines and platforms in conformance with BS EN ISO 14122-3:2016. See our handrails here.

Question 6: Why buy Mezzbarriers pallet gates?

Answer: The Mezzbarriers range differs from other pallet gate systems and methods of construction, various advanced features are incorporated into the design, production and finish with the clear aim of optimizing the high quality and long life of the product.

Vibration resistant Interclamp® fittings with stainless steel screws for increased corrosion resistance have been subjected to stringent vibration endurance resistance tests by an accredited independent test laboratory. In high quality galvanized finish – Interclamp components and tube are hot-dipped galvanized to BS EN ISO 1461:2009 giving a corrosion-resistant finish for extended life.

Special high-strength fabricated bolted components, where needed to protect excessive leverage weak points are zinc sprayed finish. Pivot points have no-maintenance nylon bushes.

Kick plates are in aluminum material. 6063T6.- Alloy tube is used in some wider models to reduce operator fatigue.

All parts are replaceable in the event of damage.

Question 7: Do your pallet gate have a Health and Safety Executive (HSE) approval?

Answer: Our double gate systems comply HSE guideline and are in conformance with BS EN ISO 14122-3:2016 in design and test criteria for mezzanine gates.

Additional benefits:

- Modular flexibility - Modular system designs adapt to on-site conditions with the flexibility to retrofit, replace broken sections or can be disassembled for repositioning when required.

- Flatpack palletized delivery - Main sections pre-assembled.

- No-weld assembly of components eliminates the need for hot works permits and site shutdowns to deliver a safer, quicker set-up and installation with little or no damage to the finish.

- Reduced corrosion - Hot dip galvanized or safety yellow thermoplastic tube coat with galvanized tube clamps with stainless steel hex screws.

Safe operation of your pallet gate

Please ensure anyone who operates your Safety Pallet Gate reads and understands the safe use section of the manual provided with your new pallet gate.

The gate must only be operated by authorized and trained personnel.

Pallet Gate Maintenance

● Periodically examine that the gate assembly is fixed securely to the floor.

● Ensure all screws and bolts are tight. Ensure that the gate mechanism is operating smoothly and that both edge gates are aligning correctly.

● Check the nylon pivot bushes for wear. No lubrication is required

● Any impact damage should be accessed to ensure the gate will continue to operate correctly.

● If these instructions are adhered to, then your pallet gate should provide you with many years of service. But should any damage occur all replacement parts are readily available from our stock.