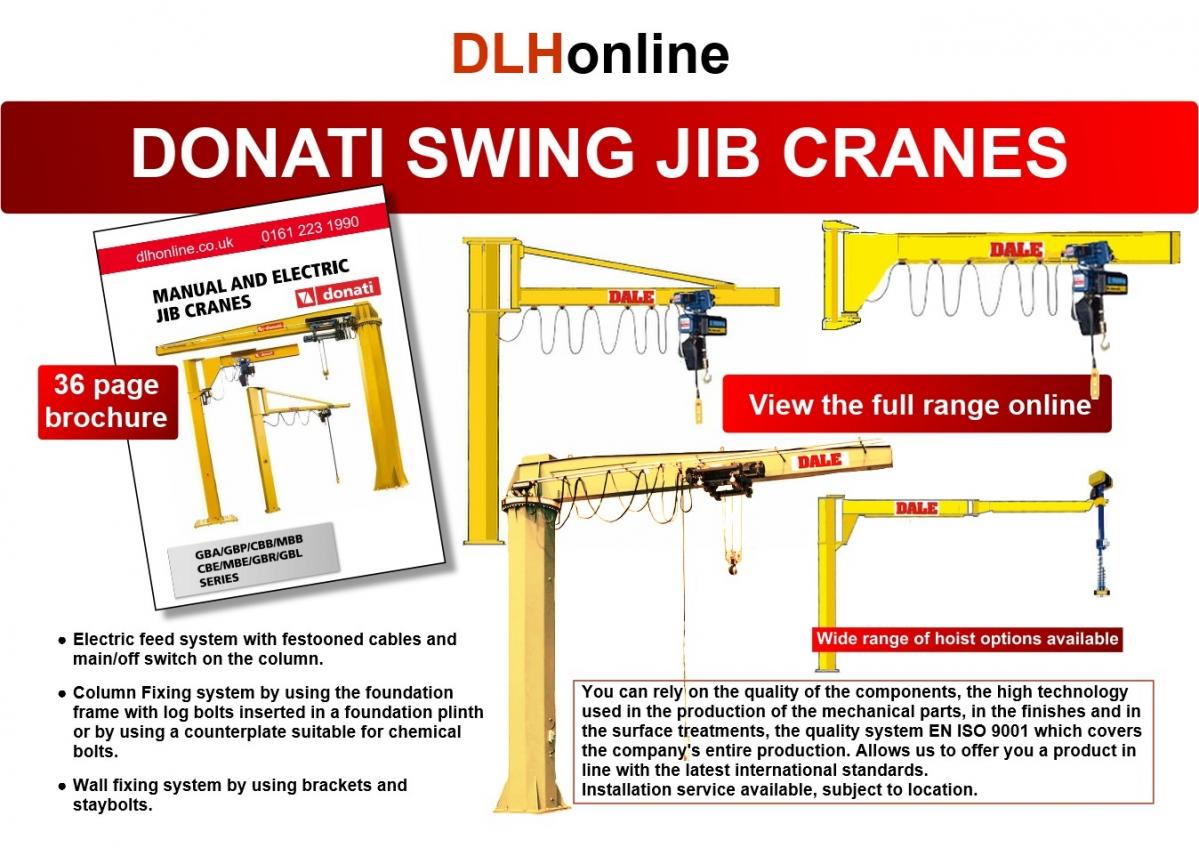

To download the Donati Jib Crane Brochure CLICK HERE

To View, the Donati range of hoists and jib cranes CLICK HERE

"The Donati range of jib cranes is second to none and we have no hesitation in recommending these products"

Paul Kildunne - Project Manager, DALE Lifting and Handling Specialists.

The Donati Jib crane range:

The manually rotated jib cranes in the GBA” column” series and the GBP “wall” series are designed for the handling of goods inside a plant, in a square or to serve operative positions.

The standard models are available for lifting capacities from 125 kg to 2000kg and jibs from 2m to 8m

The C-T-H versions are designed according to the three different versions of the arm.

“C” Channel version for lifting capacities from 63kg to 1000kg and jibs from 2m to 7m

The arm is made using a special section bar made of folded sheet metal, inside which the hoist-carrying trolley run.

The arm is fitted with one or two stay bolts that support the profile and connect it to the rotation tube.

This version is characterised by the extreme ease of handling due to the low inertia derived from its own reduced weight.

The arm is normally fitted with a special “channel” profile trolley, which allows it to be pushed with maximum fluidity.

“T” cantilever version, for lifting capacities from 63kg to 2000kg and jibs from 2 m to 5 m

The arm is made using a laminate T-beam form: the hoist-carrying trolley runs on the lower flange of the T-beam.

The girder is self- supporting and cantilevered, so it has no support stay bolts, and it is directly integrated with, via suitable reinforcements, the rotation tube.

This version allows the optimum use of the available space at a height due to the absence of stay bolts and allows the maximum use of the hook run. The arm allows the addition of electrical or mechanical push-trolleys.

“H” over braced version, for lifting capacities from 125kg to 2000kg and jibs from 4m to 8m

The arm is made using an H-beam section, the hoist-carrying trolley runs on the lower flange of the H-beam. The arm is fitted with one or two stay bolts to support the profile which connects it to the rotation tube.

This version allows the use of the jib crane for loads and jibs superior to those possible with the C and T versions. The arm allows the addition of electrical and mechanical push-trolleys.

electrical power supply

This is designed to power the hoist and/or electrical trolley, which runs along the jib of the crane. It uses a connection box for the connection between the line and the power festoon.

CBB: “column with articulated arm” series Maximum rotation field 360°

MBB: ”wall with articulated arm” series Maximum rotation field 360°

The manually rotated jib cranes with an articulated arm in the CBB ”column” series and the MBB ”wall” series, are designed for the handling of goods inside a plant or a building site where the presence of fixed obstacles would impede the free rotation in terms of the mobility of the arm when it is formed by one rigid element.

The cranes “with an articulated jib” are fitted with an arm made of two hinged “pantograph-shaped” segments which allow it to avoid fixed obstacles during rotation.

The standard models are available for lifting capacities from 125 kg to 500 kg and jibs from 2 m to 7 m. In the version designed for the application of manipulators, the maximum load is 125 kg.

Articulated jib

The jib cranes, both in the wall and column versions, are fitted with an “articulated arm”, which rotates on its own axis. The articulated arm is made using two cantilevered girders, which form the two hinged segments (semi-arms).

The semi-arm on the “tie” side is generally made in the boxed casing, while the “cantilever” side can be made using a T-beam or a tubular profile. cable, situated on the top of the column crane or near the bracket support in the wall version.

The column crane can be supplied, on request, with a main on/off line switch which can be padlocked. The distribution of energy takes place via a flat festoon cable which slides on a trolley along the arm.electrical power supply

This powers the hoist and for the connection between the line and the power cable has a Terminal box near the support bracket in the MBB wall version.

A main on/off line switch which can be padlocked is positioned on the column in the CBB version.The distribution of energy takes place via cable. Electrical line with the round multipolar flexible cable inserted in a channel welded under the flange of the jib. Push-button panel hanging from the hoist.

CBE: “column” series Maximum rotation field 300° (290° in the T version)

MBE: “wall” series Maximum rotation field 270° (250° in the T version)

The electrically rotated jib cranes with a motorised arm in the CBe” Column” version or the MBE “wall” version are designed for handling goods in areas that are difficult to reach, where the presence of fixed obstacles would impede the practicability of the working area.

They are used also when the frequency of maneuvers, the entity of the load and the push forces, could cause excessive wear and tear if carried out manually.

Available in standard versions for lifting capacities from 250 kg to 2000kg and jibs from 2m to 8m, in T and H models according to the different layouts of the arm.

“T” cantilever version, for loads from 500kg to 2000kg and jibs from 3m to 6m

Made using solid section T-beam: the hoist-carrying trolley runs on the lower flange of this. The girder is self-supporting and cantilevered, so without support stay bolts, and is directly integrated with, via suitable reinforcements, the rotation tube.

This version allows the optimal use of the available space at a height due to the absence of stay bolts and allows the maximum use of the hook run. The arm allows the addition of electrical or mechanical push-trolleys.

“H” over braced version, for lifting capacities from 250 kg to 2000kg and jibs from 4m to 8m

Made using an H-beam section girder, where the hoist-carrying trolley runs on the lower flange. The arm is fitted with one or two stay bolts to support the profile which connects it to the rising rotation tube.

This version allows the use of the jib crane for lifting capacities and ranges superior to those of the T version. The arm allows the addition of electrical or mechanical push-trolleys.

Rotating Arm

The arm, swiveling on its own axis on revolving bearings, is formed by a supporting girder for the run of the hoist- carrying trolley. the rotation mechanism formed by a motor reducer fixed vertically in the lower part of the support bracket, made with a reducer of epicycloidal type, with gears in a permanent oil and self- braking conical brake motor.

The drive sprocket of the motor reducer fits together with a toothed crown integral with the arm which it powers. The progressive starting up and braking is ensured by a variator of frequency (inverter) powered by alternate monophase power with 230V voltage.

Electrical power supply

To power the hoist and the trolley which run along the arm of the crane as well as the rotation motor reducer. The power supply includes two electrical control panels, one for the control of the lifting and travel unit of the hoist, while the rotation control equipment is integrated with the motor reducer.

Inside the panels, the contactors for the control of all the movements of the crane are positioned. The control circuits are low voltage (48V) obtained via a transformer protected by fuses. An easy-to-use connection terminal box, with numbered terminals, ensures simplicity and safety of the cabling of the cables related to all the external functions making any inspection easy to perform.

Power line to power the trolley-hoist formed by flexible flat multipolar cables festooned on the sliding trolleys on the lower flange of the beam.

Push-button control panel, suspended on the hoist, with a case in shockproof thermoplastic, supported by a self-supported round multipolar cable. When necessary it is fitted with a rapid socket with obliged polarity to make it easier to assemble and to replace.

On request, an independent, sliding, push-button panel can be installed along the jib of the crane, via cable-carrying sleds running inside a channel profile.

Acoustic alarm, when included, controlled by an “alarm” button serves the function of acoustic warning to indicate any dangerous situations during handling.

Electric safety limit switch on the rotation movements, installed as standard to delineate the rotation field of the arm of the crane.

Working on the auxiliary circuits at low voltage, two thresholds of intervention both in right rotation and left also carries out the emergency function in safety if there is any breakdown or malfunctioning of the first threshold of intervention.

For the connection to the line there is:

- on the jib crane a main on/off line switch which can be padlocked

- on the bracket crane a connector block. Powered by alternate electric power with three-phase voltage + neutral+earth (- 3+N+T).

Series GBR: 360° slew

The GBR series electrically rotated jib cranes are used to handle loads whose mass (high or bulky) does not allow manual handling. They are also used when fixed obstacles impede the practicability of

the working surface.

They are the ideal solution for handling:

- in outdoor squares or deposits

- on wharves, to load and unload materials for watercraft

- on wharves to haul boats

- on loading ramps, for handling materials for lorries

- for services of big operating units or assembling machines

Available as standard for lifting loads from 1000kg to 10,000kg and jibs from 4m to 10.5m.

Column

Made of a press-forged steel section welded to the tubular structure with the polygonal section it allows a high rigidity and stability; it is fixed with a base plate and a system of bolts and log bolts. The upper part is fitted with a flange for fixing the rotation thrust bearing.

Rotating arm

This is formed by a supporting girder and, in relation to the lifting capacity and/or the jib length, can be made with an H beam or with a box beam designed to guarantee the maximum flexo-torsional stability. In the construction of the box beam high-quality section steel is used and welding carried out with continuous line procedure to ensure optimal safety conditions and operative reliability of the crane.

It is fitted with a flange with holes for the application of the thrust bearing to which it is fixed using high resistance bolts.

The rotation of the arm of the crane, which is mounted on a rotating thrust bearing, is ensured via a motor reducer.

The circular area served by the arm can, according to necessity, be limited by electrical limit switches, or allow continual rotation, without end, of the arm itself in both directions by a collector ring.

Rotation mechanisms

Base bearing or thrust bearing, able to support both axial pushes, due to vertical forces and the tilting momentum due to the movement.

Motoreducer, fitted on the arm, fitted with a self- braking motor with progressive start-up and braking where the sprocket keyed on the slow shaft fits together with the internal toothing of the thrust bearing to which it gives movement.

Fixing system

The foundation frame with log bolts is supplied, on request,

for fixing the column to the base (foundation plinth).

Electrical power supply

Made for powering the hoist and trolley which run along the arm of the crane as well as to power the rotation motor reducer and includes two electrical control panels, one to control the lifting and moving onboard the trolley/hoist unit, while the control apparatus of the rotation motor reducer is integral with to the arm. Inside the panels, there are the contactors for the control of all the movements of the crane, as well as protection fuses against short circuits.

The control circuits are at low voltage obtained via a transformer protected by fuses. A connection terminal box, with numbered terminals, ensures the simplicity and safety of the cabling of the cables relative to all the external functions making any inspection easy to perform.

Alternatively, on request, the crane can be supplied with one electrical panel only made of press-forged sheet, which contains the contactors and the timers to control all the movements of the crane, as well as protection fuses against short circuits. The control circuits are low voltage. A connection terminal box ensures the simplicity and safety of the cabling of the cables relative to all the external functions. making any inspection easy to perform. The electrical line to power the trolley-hoist formed of flat flexible multipolar cables festooned on the trolleys which slide inside a channel section.

A hanging push-button control panel, with a shockproof thermoplastic casing, sliding, along the crane girder, via trolleys inside a channel section using festooned flexible multipolar cable.

It is supported by a self-supported round multipolar cable.

It is generally fitted with a connector with fast connectors and obliged polarity, to make assembly and replacement easier.

Acoustic alarm, when necessary, controlled using an “alarm” button it serves the function of acoustic warning to indicate any dangerous situations during handling.

Rotating collector ring installed when the arm of the crane is free from obstacles in every point of its rotation and the arm itself is required to rotate continuously in both directions.

Electric safety limit switches on the movements of rotation installed to limit the rotation field of the arm of the crane. Acting on the low voltage auxiliary circuits, with two intervention thresholds both rotating right and left and it serves the function of emergency in safety in case of any breakdown or malfunctioning of the first intervention threshold.

The range of products covers every aspect of industrial lifting offering unbeatable value for money together with pleasing, professional design.

The DMK electric chain hoists for lifting loads up to 4000kg, the manually and electrically rotated jib cranes, the DRH wire rope hoists with lifting capacity up to 40.000kg,

The special versions of each product, on request some also with CSA/UL homologation, complete the range guaranteeing an answer to the most varied and specific application needs.

The constant attention paid by DONATI SOLLEVAMENTI S.r.l to the maximum satisfaction of its clients is focused on creating a long-term relationship of mutual esteem and trust thanks to the flexibility and promptness of its organization and the direct personal touch. The after-sales service aims to resolve problems immediately whether they involve spare parts, assistance or guarantee.

To View, the Donati range of hoists and jib cranes CLICK HERE