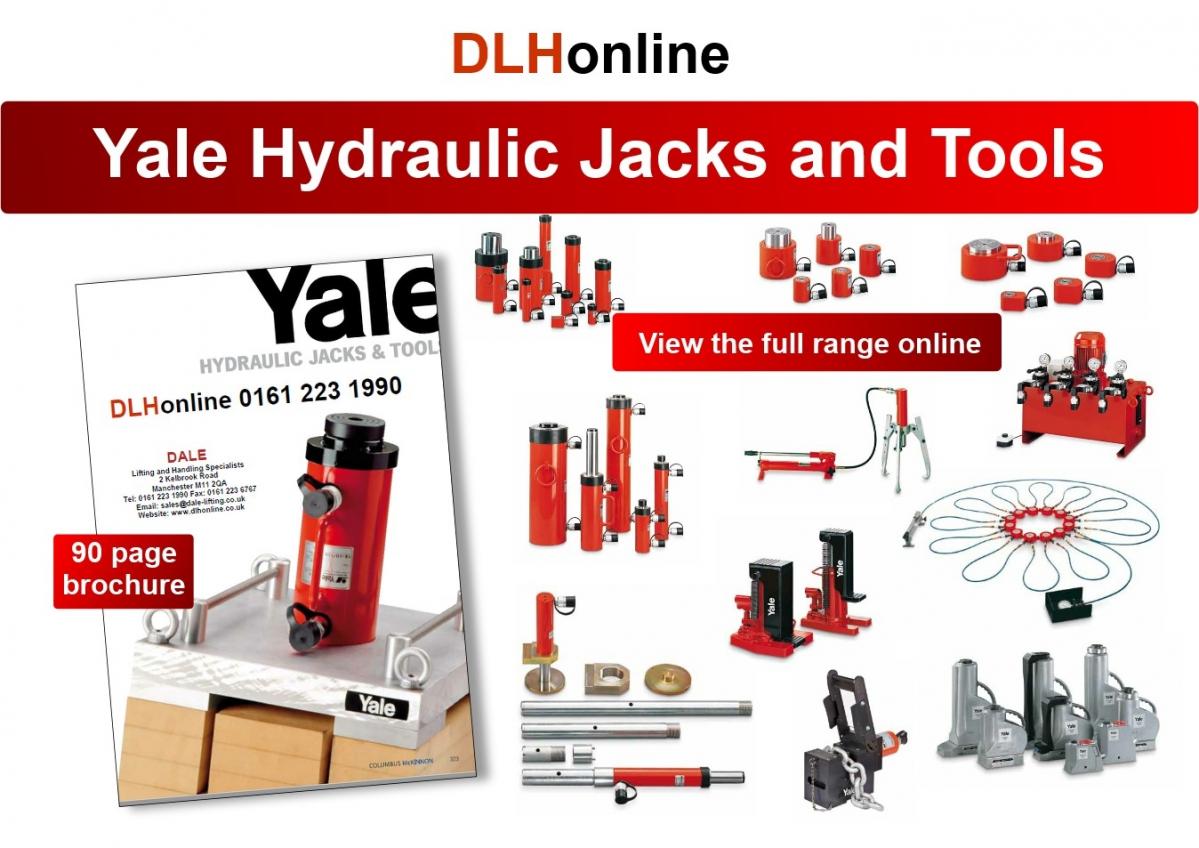

Hydraulic Jacks and Tools

Hydraulic tools are a special type of power tool, which can be used for general assembly and repair jobs with preferably high force in the lowest spaces. Simple applications, clearness of the program in line with robustness, short-term deliveries, and universal operation possibilities have made Yale hydraulic components indispensable tools also for elaborate functions.

The unlimited power of hydraulic tools is used in applications like lifting, leveling and positioning of heaviest loads, installations of machines, assembly of complex structures as well as in general repair of maintenance jobs. The components can also be operated in fixtures for clamping, testing, pressing, extracting, crimping, cutting, riveting and many more.

How to reach high forces in hydraulics?

area x pressure = force effective piston area x system pressure = force cm² x bar = daN

Example: Hydraulic cylinder YS-10/ 14.3 cm² x 700 bar = 10010 daN = 100 kN = 10 t

Linear conversion of pressure force

The above formula shows that pressure forces can be converted linearly.

Example:

A 10 ton cylinder presses at: 700 bar - 100 kN = 10 t 350 bar - 50 kN = 5 t 100 bar - 14 kN = 1.4 t 1 bar - 0.14 kN = 0.014 t.

The system pressure determines the force of the hydraulic cylinder. The oil displacement determines the piston travel speed

Basic terms in hydraulics

The pressure is the system pressure generated by the pump, which, however, can also be produced by an external power source, which acts on the hydraulic cylinder.

Force is always the pressure transferred by the hydraulic cylinder (only with counterpressure).

Stroke is the travel distance to be achieved by the force (no-load stroke, loaded stroke, return stroke).

Piston travel speed Is the time, in which the piston of the hydraulic cylinder is to pass a certain travel distance (stroke) (no-load stroke + loaded stroke, return stroke).

Hydraulic cylinders are available in many different designs, however, with only two basic function principles:

Hydraulic hand pumps

The function of a hydraulic hand pump is to convey hydraulic oil (no-load stroke) and to generate pressure, which will be converted by the hydraulic cylinder into force (loaded stroke).

Hydraulic hand pumps are independent of energy and can be used in every-day applications. They are easily portable and render an extremely high power generation in connection with a corresponding hydraulic cylinder.

Hand pumps require certain manpower and are often replaced by motor pumps in case of permanent duty and high oil quantities, respectively.

Hand pumps are distinguished by:

1. oil displacement volume (1st stage /2nd stage).

2. the function of the hydraulic cylinder: single-acting /double-acting.

Motor pumps

transmit an oil flow as soon as the pump unit is driven by the electric motor. Contrary to hand pumps, the oil flow is also available when the hydraulic cylinder is not activated (e.g. during work breaks).

Hydraulic valves

Valves are used in hydraulics to control the oil flow (generated by either hand or motor pump) in terms of direction, pressure and oil volume.

Directional valves

Valves are required to control the direction of the oil flow and thus the work motions of the connected hydraulic cylinder (advance – stop – retract). Depending on the type of pump and cylinder, 2-, 3- or 4-way valves may be employed. 3/3-way valves for single-acting cylinders 4/3-way valves for double-acting cylinders

Controls

Controls are available with either manual or electromagnetic valves (the latter with remote cable control).

Pressure valves

Pressure valves are employed to limit the system pressure in a hydraulic system or within a part of the oil circuit. Pressure valves or pressure relief valves are also installed as safety devices in order to avoid the excessive increase of the system pressure beyond a given value.

Shut-off and throttle valves

These are used to easily shut-off hydraulic lines by hand. On account of their sensible control mode, these valves can also be applied to throttle an oil flow and thus to control the piston advance at both lifting or lowering of the load.

Safety check valves

These are used for those applications where pressure drops must be avoided.

Pressure switches

The pressure switch can be set to any pressure value in order to switch on/off parts of the hydraulic circuit.

For more information on Yale hydraulic jacks and tools download the Yale 90 page brochure PDF

To view Yale Hydraulic jacks and tools online and request a quotation. CLICK HERE