High-level opening used for loading operations poses a serious risk of falls from height. Industrial, commercial roller shutter doors and conventional swing doors have particularly critical health and safety risks.

Traditionally these openings have been protected by removable bars or chains. These do not meet HSE guidelines as they are dangerous to operate, by bringing workers into proximity danger of falling from an unprotective edge. To mitigate the danger safety managers have given the operative a safety harness to wear during loading operations. However, these can only work if the operative remembers to put in on and importantly it does not protect other personnel who may approach the exposed opening from the risk of falling.

Typical examples for upper-level door openings are plant rooms with hoist loading facilities for maintenance purposes or cleanroom loading doors for palletised goods in the pharmaceutical and food sectors.

The main problem with positioning a pallet gate in a door opening is that roller shutter doors or inward opening doors are usually mounted on the internal face of the wall. Which can mean that, depending on the wall thickness, there is a considerable distance from the inside face of the door to the loading edge. A standard up and over pallet gate positioned behind the door is generally too far back from the edge for the forklift operator to position the pallet for the gate to close properly over the pallet. This problem is even further exacerbated if there is an external ledge.

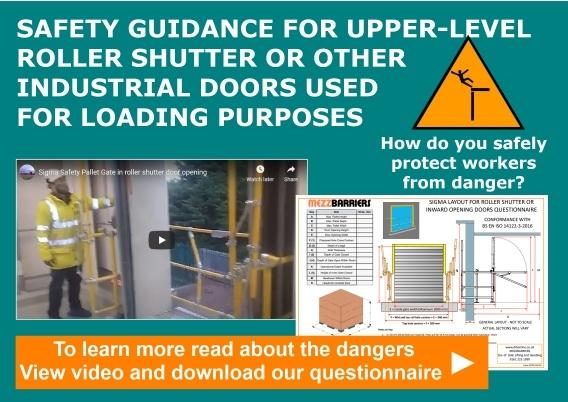

How do you safely protect workers from the dangers?

Mezzbarriers division of DALE Lifting and Handling Specialists has developed an interconnected internal/external safety barrier system which guards the open doorway during the loading operation. The system guards the edge at all times when the door is open. The dual-gate system has side frame mechanisms connected through drilled holes on either side of the door frame allowing the edge gate to be mounted externally. To open the outer gate, the operative must pull down the fold-up inner gate which surrounds and protects the opening area during loading operations.

The system has been designed for installation by customers own personnel and requires no power supply in use and is easy to operate and maintain. Constructed with a high-quality tube clamp system, all parts are replaceable in the event of damage. The finish is all galvanised or optional safety yellow thermoplastic tube coating suitable for both indoor or outside weather conditions. The design meets the requirements of BS EN ISO 14122-3:2016 for pallet gates

To make specification simple there is a downloadable questionnaire with illustrations showing all the measurements’ required to obtain your no-obligation quotation.

| Download Questionnaire |

Need to arrange a demonstration* or talk to an expert - Call 0161 223 1990 or Email mezzbarriers@dale-lifting.co.uk

*By appointment at our Manchester works dedicated demonstration area.