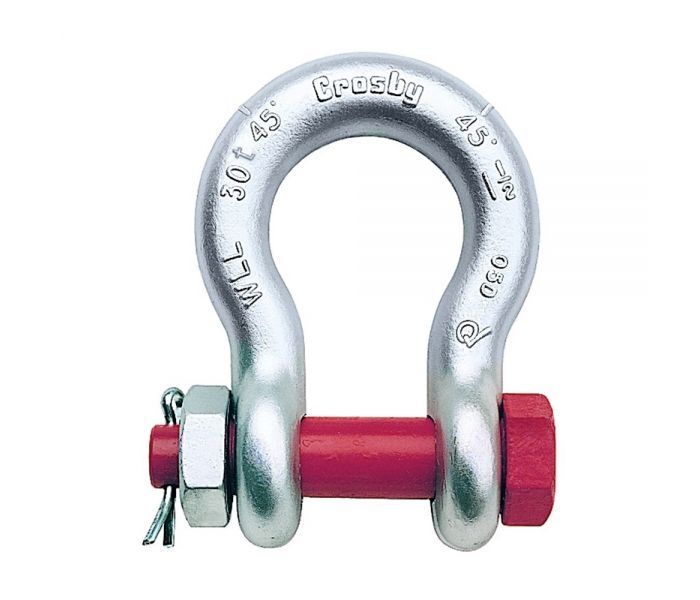

CROSBY G2130 - BOLT TYPE ANCHOR ( SAFETY BOW ) SHACKLES - Crosby - By Brand

CROSBY G2130 - BOLT TYPE ANCHOR ( SAFETY BOW ) SHACKLES

Key Features

- Capacities 1/3 thru 150 metric tonnes, grade 6.

- Working Load Limit and grade “6” permanently shown on every shackle.

- Forged — Quenched and Tempered, with alloy pins.

- Hot Dip galvanised and the bolts are Dimetcoted® and painted red)

- Sizes 1/2t-25t meet the performance requirements of EN13889:2003.

Delivery Information

Order online for delivery to Mainland UK VAT eligible locations only. Delivery charges will be shown in the shopping cart. Despatch dates for products can vary, if urgent, please contact us. Request a quote for postcodes DD, IV, KW, PA, AB, BT, HS, TR. PO30-PO42, southern Ireland, Channel Islands. For international destinations restrictions may apply.

Returns Policy

Simply email us at sales@dale-lifting.co.uk or call 0161 223 1990 and we will be able to give you a returns authorisation code, which must be sent with the returned item. Returns should be authorised within 14 days from the day of delivery to you. Items should be returned in unused condition & due to the nature of our products a restocking fee may apply. Unfortunately, delivery charges are not refundable. Items returned without an authorisation code may not be accepted. Normally All refunds will be processed within 7- 10 working days on receipt of returned goods.

Non-standard (Quote only, pre-order or custom-made products)

Custom made to order products are not covered by our returns policy. Please ensure when ordering all measurements and capacities are correct as we are unable to refund on these products.

For more information see https://www.dlhonline.co.uk/terms-conditions

CROSBY G2130 - BOLT TYPE ANCHOR ( SAFETY BOW ) SHACKLES

- Capacities 1/3 thru 150 metric tonnes, grade 6.

- Working Load Limit and grade “6” permanently shown on every shackle.

- Forged — Quenched and Tempered with alloy pins.

- Hot Dip galvanised and the bolts are Dimetcoted® and painted red)

- Fatigue rated (1/3t - 55t).

- Shackles 25t and larger are RFID EQUIPPED.

- Approved for use at -40 degrees C (-40 degrees F) to 204 degrees C (400 degrees F).

- 2t through 25t bow and bolt are Certified to meet Charpy impact testing of 42 joules (31 ft-Ibs.) min. ave. at -20 degrees C (-4 degree F)

- Meets or exceeds all requirements of ASME B30.26.

- Sizes 1/2t-25t meet the performance requirements of EN13889:2003.

- Shackles 55 metric tonnes and smaller can be furnished proof tested with certificates to designated standards, such as ABS, DNV, Lloyds, or other certifications when requested during order.

- Shackles 120 metric tonnes and larger are proof tested, Magnetic Particle Inspected, and provided with Serialized Pin and Bow.

- Type Approval and certification by ABS 2006 Steel Vessel Rules 1-1- 17.7 and ABS Guide for Certification of Cranes.

- 3.1 Certification as standard available for charpy and statistical proof test for pg 73 only up to 25 tons to DNV2.7-1 and EN13889.

- Crosby 2t through 25t G2130 anchor shackles are type approved to DNV Certification Notes 2.7-1- Offshore Containers. These Crosby shackles are statistically proof and impact-tested. Crosby conducts the tests, and 3.1 test certification is available upon request

- Requirements of DNV rules for certification of lifting applications - Loose Gear.

- All other 2130 and all 2150 shackles can meet charpy requirements of 42 joules(31 ft-Lbs) average at -20 degrees C (-4 degree F) upon special request.

- Look for the Red Pin® . . . the mark of genuine Crosby quality.

| NominalSize (in.) | WorkingLoadLimit(t)* | StockNo. | WeightEach(kg) |

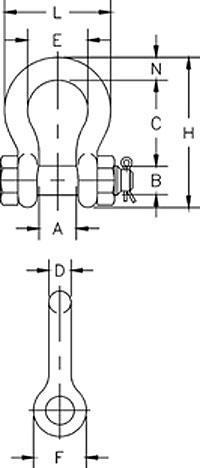

Dimensions (mm) | Tolerance + / - |

|||||||||

| G-2130 |

A |

B |

C |

D |

E |

F |

H |

L |

N |

C |

A |

|||

| 3/16 | 1/3 ‡ | 1019464 | .03 | 9.65 | 6.35 | 22.4 | 4.85 | 15.2 | 14.2 | 37.3 | 24.9 | 4.85 | 1.50 | 1.50 |

| 1/4 | 1/2 | 1019466 | .05 | 11.9 | 7.85 | 28.7 | 6.35 | 19.8 | 15.5 | 46.7 | 32.5 | 6.35 | 1.50 | 1.50 |

| 5/16 | 3/4 | 1019468 | .10 | 13.5 | 9.65 | 31.0 | 7.85 | 21.3 | 19.1 | 53.0 | 37.3 | 7.85 | 3.30 | 1.50 |

| 3/8 | 1 | 1019470 | .15 | 16.8 | 11.2 | 36.6 | 9.65 | 26.2 | 23.1 | 63.0 | 45.2 | 9.65 | 3.30 | 1.50 |

| 7/16 | 1-1/2 | 1019471 | .22 | 19.1 | 12.7 | 42.9 | 11.2 | 29.5 | 26.9 | 74.0 | 51.5 | 11.2 | 3.30 | 1.50 |

| 1/2 | 2 | 1019472 | .36 | 20.6 | 16.0 | 47.8 | 12.7 | 33.3 | 30.2 | 83.5 | 58.5 | 12.7 | 3.30 | 1.50 |

| 5/8 | 3-1/4 | 1019490 | .62 | 26.9 | 19.1 | 60.5 | 16.0 | 42.9 | 38.1 | 106 | 74.5 | 17.5 | 6.35 | 1.50 |

| 3/4 | 4-3/4 | 1019515 | 1.23 | 31.8 | 22.4 | 71.5 | 19.1 | 51.0 | 46.0 | 126 | 89.0 | 20.6 | 6.35 | 1.50 |

| 7/8 | 6-1/2 | 1019533 | 1.79 | 36.6 | 25.4 | 84.0 | 22.4 | 58.0 | 53.0 | 148 | 102 | 24.6 | 6.35 | 1.50 |

| 1 | 8-1/2 | 1019551 | 2.28 | 42.9 | 28.7 | 95.5 | 25.4 | 68.5 | 60.5 | 167 | 119 | 26.9 | 6.35 | 1.50 |

| 1-1/8 | 9-1/2 | 1019579 | 3.75 | 46.0 | 31.8 | 108 | 28.7 | 74.0 | 68.5 | 190 | 131 | 31.8 | 6.35 | 1.50 |

| 1-1/4 | 12 | 1019597 | 5.31 | 51.5 | 35.1 | 119 | 31.8 | 82.5 | 76.0 | 210 | 146 | 35.1 | 6.35 | 1.50 |

| 1-3/8 | 13-1/2 | 1019613 | 7.18 | 57.0 | 38.1 | 133 | 35.1 | 92.0 | 84.0 | 233 | 162 | 38.1 | 6.35 | 3.30 |

| 1-1/2 | 17 | 1019613 | 8.62 | 60.5 | 41.4 | 146 | 38.1 | 98.5 | 92.0 | 254 | 175 | 41.1 | 6.35 | 3.30 |

| 1-3/4 | 25 | 1019659 | 15.4 | 73.0 | 51.0 | 178 | 44.5 | 127 | 106 | 313 | 225 | 57.0 | 6.35 | 3.30 |

| 2 | 35 | 1019677 | 23.7 | 82.5 | 57.0 | 197 | 51.0 | 146 | 122 | 348 | 253 | 61.0 | 6.35 | 3.30 |

| 2-1/2 | 55 | 1019695 | 44.6 | 105 | 70.0 | 267 | 66.5 | 184 | 145 | 453 | 327 | 79.5 | 6.35 | 6.35 |

| 3 | † 85 | 1019711 | 70 | 127 | 82.5 | 330 | 76.0 | 200 | 165 | 546 | 365 | 92.0 | 6.35 | 6.35 |

| 3-1/2 | † 120 ‡ | 1019739 | 120 | 133 | 95.5 | 372 | 92.0 | 229 | 203 | 626 | 419 | 105 | 6.35 | 6.35 |

| 4 | † 150 ‡ | 1019757 | 153 | 140 | 108 | 368 | 104 | 254 | 229 | 653 | 468 | 116 | 6.35 | 6.35 |