CROSBY G2140 - BOLT TYPE ANCHOR ( SAFETY BOW ) SHACKLES - Lifting Shackles - Lifting, Hoisting and Winching

CROSBY G2140 - BOLT TYPE ANCHOR ( SAFETY BOW ) SHACKLES

Key Features

- Quenched and Tempered.

- Alloy bows, Alloy bolts.

- Forged Alloy Steel 2 thru 200 metric tons. Cast Alloy Steel 250 thru 400 metric tons. Meets performance requirements of Grade 8 shackles

- Working Load Limit is permanently shown on every shackle.

- All sizes are individually proof tested to 2.0 times the Working Load Limit.

Delivery Information

Order online for delivery to Mainland UK VAT eligible locations only. Delivery charges will be shown in the shopping cart. Despatch dates for products can vary, if urgent, please contact us. Request a quote for postcodes DD, IV, KW, PA, AB, BT, HS, TR. PO30-PO42, southern Ireland, Channel Islands. For international destinations restrictions may apply.

Returns Policy

Simply email us at sales@dale-lifting.co.uk or call 0161 223 1990 and we will be able to give you a returns authorisation code, which must be sent with the returned item. Returns should be authorised within 14 days from the day of delivery to you. Items should be returned in unused condition & due to the nature of our products a restocking fee may apply. Unfortunately, delivery charges are not refundable. Items returned without an authorisation code may not be accepted. Normally All refunds will be processed within 7- 10 working days on receipt of returned goods.

Non-standard (Quote only, pre-order or custom-made products)

Custom made to order products are not covered by our returns policy. Please ensure when ordering all measurements and capacities are correct as we are unable to refund on these products.

For more information see https://www.dlhonline.co.uk/terms-conditions

CROSBY G2140 - Alloy Anchor ( BOW ) Shackle

- Quenched and Tempered.

- G-2140meets theperformance requirements of Federal Specification RR-C-271F, TypeIVA, Grade B,

- Forged Alloy Steel 2 thru 200 metric tons. Cast Alloy Steel 250 thru 400 metric tons. Meets performance requirements of Grade 8 shackles.

- Working Load Limit is permanently shown on every shackle

- 30, 40, 55, and 85 metric ton shackle bows are available galvanized or self colored with pins that aregalvanized and painted red.

- 120, 150, 175 metric ton shackle bows are hot-dip galvanized; bolts are Dimetcote®dand painted red.

- 400 metric ton shackle bows are Dimetcoted®; bolts are Dimetcote®dand painted red

- Sizes 1-1/2 and larger are RFID EQUIPPED.

- Approved for use at-40 degrees C (-40 degrees F) to 204 degrees C (400 degrees F).

- Shackles are Quenched and Tempered and can meet DNV impact requirements of 42 joules (31 ft-lbs.) at-20 degrees C (-4 degrees F).

- All sizes are individually proof tested to 2.0 times the Working Load Limit.

- Shackles 200 metric tons and larger are provided as follows.

- Serialized pin and bow

- Material certification (chemical)

- Magnetic particle inspected.

- Certification must be requested at time of order.

- Meets or exceeds all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requiremen.ts2140 shackles meet other critical performance requirements including impact properties and material traceabtiyli, not addressed by ASME B30.26.

- Type Approval certification in accordance with ABS 2007 Steel Vessel Rules 1-11-17.7 and ABS Guide for Certification on Cranes available. Certificates available when requested at time of order and may include additional charges.

- Look for the Red Pin® ... the mark of genuine Crosby qualtiy.

G-2140IS-2140 Crosby®AlloyBolt Type Anchor Shackles

|

Nominal (in.) |

Working

|

Stock No. |

Weight

|

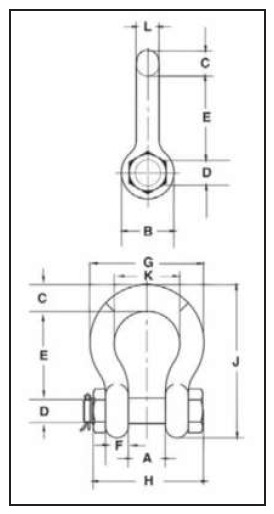

Dimensions

|

Tolerance + I - |

|||||||||||

|

G-2140 |

A |

B |

C |

D |

E |

F |

G |

H |

J |

K |

L |

A |

E |

|||

|

3/8 |

2 |

1021015 |

0.15 |

16.8 |

23.1 |

9.7 |

11.2 |

36 .6 |

9.7 |

45.2 |

55.1 |

63.2 |

26.2 |

9.7 |

1.5 |

3.3 |

|

7/16 |

2 2/3 |

1021020 |

0.22 |

19.1 |

26.9 |

11.2 |

12.7 |

42.9 |

10.4 |

51.6 |

63.8 |

73.9 |

29.5 I 11.2 I 1.5 I 3.3 |

|||

|

1/2 |

31/3 |

1021029 |

0.36 |

20.6 |

30.2 |

12.7 |

16.3 |

47.8 I 11.7 |

58.7 |

71.1 |

83.3 |

33.3 |

12.7 |

1.5 |

3.3 |

|

|

5/8 |

5 |

1021038 |

0.76 |

26.9 |

38.1 |

17.5 |

19.6 |

60.5 |

14.7 |

74.7 |

90.4 |

106.4 |

42.9 |

16.0 |

1.5 |

3.3 |

|

3/4 |

7 |

1021047 |

1.23 |

31.8 |

46.0 |

20.6 |

22.6 |

71.4 |

17.5 |

88 ,9 |

105.4 |

126.2 |

50,8 |

19.1 |

1.5 |

6.4 |

|

7/8 |

91/2 |

1021056 |

1.79 |

36.6 |

53.1 |

24.6 |

25.9 |

84.1 |

20.6 |

102.4 |

122.4 |

148.1 |

57.9 |

22.4 |

1.5 |

6.4 |

|

|

12 1/2 |

1021065 |

2.57 |

42.9 |

60.5 |

26.9 |

29.2 |

95.3 |

23.4 |

119.1 |

136.9 |

166.6 |

68.3 |

25.4 |

1.5 |

6.4 |

|

1 1/8 |

15 |

1021074 |

3.75 |

46.0 |

68,3 |

31.8 |

31.8 |

108,0 |

26.4 |

131.1 |

149.9 |

189.7 |

73.9 |

28.7 |

1.5 |

6.4 |

|

1 1/4 |

18 |

1021083 |

5.31 |

51.6 |

76. 2 |

35.1 |

35.6 |

119.1 |

29.5 |

146.1 |

169.9 |

209.6 |

82.6 |

32.8 |

1.5 |

6.4 |

|

1 3/8 |

21 |

1021092 |

7.18 |

57.2 |

84.1 |

38.1 |

38.9 |

133.4 |

32.5 |

162.1 |

183.1 |

232.7 |

92.2 |

36.1 |

3.3 |

6.4 |

|

1-1/2 |

30 |

1021110 |

8.52 |

60.5 |

91.9 |

41.1 |

41.4 |

146 |

35.3 |

175 |

196 |

254 |

98.6 |

38.9 |

3.3 |

6.4 |

|

1-3/4 |

40 |

1021138 |

15.4 |

73.2 |

106 |

57.2 |

50,8 |

178 |

44.5 |

224 |

237 |

313 |

127 |

46.7 |

3.3 |

6.4 |

|

2 |

55 |

1021156 |

23.6 |

82.6 |

122 |

61.0 |

57.2 |

197 |

50.8 |

258 |

264 |

347 |

146 |

52.8 |

3.3 |

6.4 |

|

2-1/2 |

85 |

1021174 |

43.5 |

105 |

148 |

79.2 |

69.9 |

267 |

66.5 |

324 |

345 |

455 |

184 |

68.8 |

6.4 |

6.4 |

|

3 |

120 |

1021192 |

81 |

127 |

165 |

92.2 |

82.6 |

330 |

76.2 |

371 |

384 |

546 |

200 |

79.2 |

6.4 |

6.4 |

|

3-1/2 |

t 150 |

1021218 |

120 |

133 |

203 |

111 |

95,3 |

372 |

95,3 |

432 |

448 |

632 |

229 |

91.9 |

6.4 |

6.4 |

|

4 |

-t 175 |

1021236 |

153 |

140 |

229 |

116 |

108 |

368 |

102 |

457 |

517 |

652 |

254 |

102 |

6.4 |

|

|

4 3/4 |

t 200 |

1021234 |

209 |

184 |

267 |

127 |

121 |

386 |

116 |

529 |

611 |

706 |

279 |

121 |

6.35 |

6.35 |

|

5 |

t 250 |

1021243 |

276 |

216 |

305 |

143 |

127 |

470 |

123 |

600 |

632 |

828 |

330 |

127 |

4.0 |

1.80 |

|

6 |

t 300 |

1021252 |

362 |

213 |

330 |

154 |

152 |

475 |

124 |

629 |

666 |

871 |

330 |

149 |

4.0 |

1.80 |

|

7*' |

t400 |

1021478 |

500 |

210 |

356 |

184 |

178 |

572 |

165 |

660 |

728 |

1022 |

330 |

152 |

6.4 |

6.4 |

- • Note: Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Load is 4.5 times the Working Load Limit on 2 thru 21 metric tons. For sizes 30 thru 175 metric tons, Minimum Ultimate Load is 5.4 times the Working Load Limit for 200 thru 400 metric tons, Minimum Ultimate Load is 4.times the Working Load Limit. •• Cast Alloy Steel.

t Furnished with Round Head Bolts with an eyebolt for handling. For Working Load Limit reduction due to side loading application,