CROSBY IPU10 & IPU10/J VERTICAL PLATE LIFTING CLAMP WITH HINGED LIFTING EYE - Crosby - By Brand

CROSBY IPU10 & IPU10/J VERTICAL PLATE LIFTING CLAMP WITH HINGED LIFTING EYE

Key Features

- The IPU10 vertical lifting clamp is used for the lifting, turning, moving or vertical transfer of sheet, plates, or fabrications from horizontal to vertical and down to horizontal (180°) as needed.

- The hinged hoisting eye allows for the clamp to place and lift the load from any direction

- Available in capacities of 0,5 thru 30 metric tonnes

- Wide variety of jaw openings available: 0 to 155mm

Delivery Information

Order online for delivery to Mainland UK VAT eligible locations only. Delivery charges will be shown in the shopping cart. Despatch dates for products can vary, if urgent, please contact us. Request a quote for postcodes DD, IV, KW, PA, AB, BT, HS, TR. PO30-PO42, southern Ireland, Channel Islands. For international destinations restrictions may apply.

Returns Policy

Simply email us at sales@dale-lifting.co.uk or call 0161 223 1990 and we will be able to give you a returns authorisation code, which must be sent with the returned item. Returns should be authorised within 14 days from the day of delivery to you. Items should be returned in unused condition & due to the nature of our products a restocking fee may apply. Unfortunately, delivery charges are not refundable. Items returned without an authorisation code may not be accepted. Normally All refunds will be processed within 7- 10 working days on receipt of returned goods.

Non-standard (Quote only, pre-order or custom-made products)

Custom made to order products are not covered by our returns policy. Please ensure when ordering all measurements and capacities are correct as we are unable to refund on these products.

For more information see https://www.dlhonline.co.uk/terms-conditions

CROSBY IPU10 & IPU10/J LIFTING CLAMP

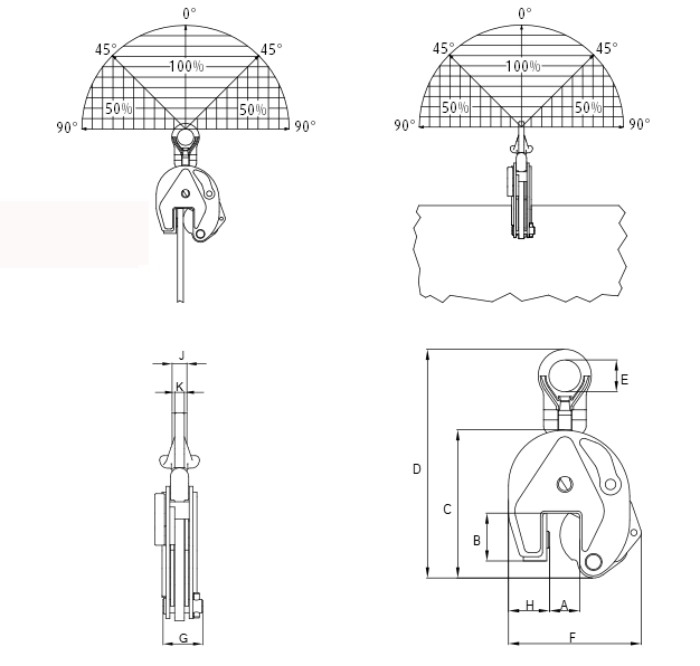

The IPU10 vertical lifting clamp is used for the lifting, turning, moving or vertical transfer of sheet, plates, or fabrications from horizontal to vertical and down to horizontal (180°) as needed. The hinged hoisting eye allows for the clamp to place and lift the load from any direction, or with a multiple leg sling without side loading the clamp.

The IPU10 lifting clamps with a WLL of 12t and up are fitted with special hook-up facilities to enable easy placement of the clamp in horizontal position.

- Available in capacities of 0,5 thru 30 metric tonnes (Higher WLL and jaw openings are available upon request).

- Wide variety of jaw openings available: 0 to 155mm | 0” - 6.13”.

- Welded alloy steel body for strength and smaller size. Forged alloy components, where required.

- Individually Proof Tested to 2 times the Working Load Limit with certification.

- Company name (CrosbyIP), logo, Working Load Limit and jaw opening permanently stamped on body.

- Each product is individually serialized, with the serial number and Proof Load test date stamped on body. Serial number is included on the test certificate with maintenance and warranty logbook.

- Full 180° turning range for material transfer, turning or moving.

- Lock open, lock closed ability with latch for pretension on material and then release of material..

- Minimum WLL of 10% of Maximum WLL.

- Maintenance replacement kits are available.

- Manufactured by a ISO 9001 facility.

- All sizes are RFID EQUIPPED.

-

model

stock no.

WLL Each (t)*

Weight Each (kg.)

Jaw a

b

C

D

E

f

g

H

J

K

0,5 IP10

2701674

0,5

1,8

0-16

44

128

207

40

115

41

28

-

10

1 IP10

2701662

1,0

2,2

0-20

45

139

215

40

126

41

38

-

10

2 IP10

2701676

2,0

7,6

0-35

78

201

336

70

190

61

55

-

16

3 IP10

2701664

3,0

13,8

0-40

100

253

436

75

225

78

60

-

20

4,5 IP10

2701666

4,5

15,0

0-40

100

253

436

75

232

82

65

-

20

6 IP10

2701668

6,0

23,5

0-50

126

302

515

80

292

84

95

40

20

6 IP10J

2701705

6,0

28,5

50-100

126

302

515

80

342

84

95

40

20

9 IP10

2701670

9,0

27,5

0-50

126

325

550

80

310

92

105

44

25

9 IP10J

2701672

9,0

28,5

50-100

126

325

555

80

360

92

105

44

25

12 IP10

2701678

12,0

49,0

0-54

160

391

580

80

331

117

137

41

25

12 IP10J

2701680

12,0

58,0

54-108

178

439

630

80

415

117

137

41

25

16 IP10

2701682

16,0

68,0

5-64

178

465

690

88

397

119

153

49

25

16 IP10J

2701684

16,0

90,0

64-128

208

521

746

88

472

119

161

49

25

22,5 IP10

2701686

22,5

108

5-80

222

554

800

110

470

136

186

49

25

22,5 IP10J

2701688

22,5

110

80-155

253

628

880

110

575

136

196

49

25

30 IP10

2701690

30,0

148

5-80

222

545

800

110

470

152

186

54

30

30 IP10J

2701692

30,0

152

80-155

250

620

880

110

565

152

196

54

30

* Design Factor based on EN 13155 and ASME B30.20.