Hackett SS-L5 Offshore Chain Lever Hoist 800 kg to 20 tonnes. (Full range) - Manual Chain Hoists - Hoists - Lifting, Hoisting and Winching

Hackett SS-L5 Offshore Chain Lever Hoist 800 kg to 20 tonnes. (Full range)

Key Features

- WORKING LOAD LIMIT RANGE: 800 kg to 20 tonnes.

- LIGHT LOAD CAPABILITY: the SS-L5 QP is tested and certified at 2% of the lever hoist rated capacity.

- DABS (DUAL ANTI-LOCK BRAKE SYSTEM): allows the load chain to be adjusted in freewheel mode without locking the brake.

- CONSTRUCTION AND DESIGN: minimises the ingress of contaminates to the internal brake mechanism surfaces.

- STAINLESS STEEL PAWL SPRINGS: specially designed to work with the SS-L5 patented quad pawls. The stainless steel springs are captivated in the brake chamber protecting them against damage.

Delivery Information

Order online for delivery to Mainland UK VAT eligible locations only. Delivery charges will be shown in the shopping cart. Despatch dates for products can vary, if urgent, please contact us. Request a quote for postcodes DD, IV, KW, PA, AB, BT, HS, TR. PO30-PO42, southern Ireland, Channel Islands. For international destinations restrictions may apply.

Returns Policy

Simply email us at sales@dale-lifting.co.uk or call 0161 223 1990 and we will be able to give you a returns authorisation code, which must be sent with the returned item. Returns should be authorised within 14 days from the day of delivery to you. Items should be returned in unused condition & due to the nature of our products a restocking fee may apply. Unfortunately, delivery charges are not refundable. Items returned without an authorisation code may not be accepted. Normally All refunds will be processed within 7- 10 working days on receipt of returned goods.

Non-standard (Quote only, pre-order or custom-made products)

Custom made to order products are not covered by our returns policy. Please ensure when ordering all measurements and capacities are correct as we are unable to refund on these products.

For more information see https://www.dlhonline.co.uk/terms-conditions

The William Hackett second-generation SS-L5 offshore lever hoist has been the first offshore lever hoist to be awarded by DNVGL ‘Saltwater Immersion test verification, Report No. A0359376.02, Rev.1. The report verifies that the SS-L5 type lever hoist could be safely used over a 21-day single immersion and a 31 day multi immersion period. The design features, testing and guidance for use, maintenance, and storage of the SS-L5 has also been developed in line with:

- BP document DEV-AAD-SS-SD-BP-0545 ‘specification and compliance requirements for lever hoists used subsea on BP projects.’

- IMCA DO28 Rev. 1 ‘Guidance on the use of chain lever hoists in the offshore subsea environment’

- IMCA Document SEL-019:2007, Guidance for Lifting Operations

The SS-L5 also meets and exceeds the requirements of international standards

British and European Standard BS EN13157: 2004 + AI: 2009

American Standard ASME B30.21-2014

Australian Standard AS 1418.2-1997

South African SANS 1636:2-2007

NORSOK R-002: 2017.

The William Hackett SS-L5 offshore lever hoist is manufactured in accordance with EN13157 which requires that it can be used within an operating temperature range of -40°C to +200°C.

The design and specification of the William Hackett SS-L5 offshore lever hoist include:

- WORKING LOAD LIMIT RANGE: 800kg to 20 tonnes.

- LIGHT LOAD CAPABILITY: the SS-L5 is tested and certified at 2% of the lever hoist rated capacity.

- DABS (DUAL ANTI-LOCK BRAKE SYSTEM): allows the load chain to be adjusted in freewheel mode without locking the brake.

- CONSTRUCTION AND DESIGN: minimises the ingress of contaminates to the internal mechanism and brake surfaces.

- STAINLESS STEEL PAWL SPRINGS: secured internally to reduce the risk of damage.

- STAINLESS STEEL FIXINGS: All internal springs are stainless steel, circ clips securing the pawls onto the pawl stands, stainless steel nyloc nuts and socket head cap screw are used to secure all hook housing

- SINTERED/FUSED FRICTION MATERIAL: directly onto the ratchet gear. Grooves in the friction material enable water to be dispelled from the friction surface more effectively during subsea operations.

- LOAD CHAIN: complies fully with BSEN818-7 Grade T(8). Finish: Zinc plated.

- CORROSION PROTECTED: The complete brake mechanism is corrosion protected including the pinion shaft, disc hub, change gear, ratchet gear, pawls, pawl stands, and load sheave. In addition, the load chain guide, stay bolt and chain stripper are also corrosion protected.

- HIGH-PERFORMANCE WATERPROOF GREASE: used throughout the hoist enhancing the corrosion protection.

- ADJUSTABLE TRAVELLING END STOP: the uniquely designed traveling end stop allows the operator to position the end stop at any point along the slack section of the load chain. When the lever hoist is in a final rigged position the traveling end stop can be positioned adjacent to the SS-L5 offshore lever hoist body. This has the function of preventing payout of the chain for whatever reason when the lever hoist is operated again

- OVERLOAD LIMITER: available as an option upon request

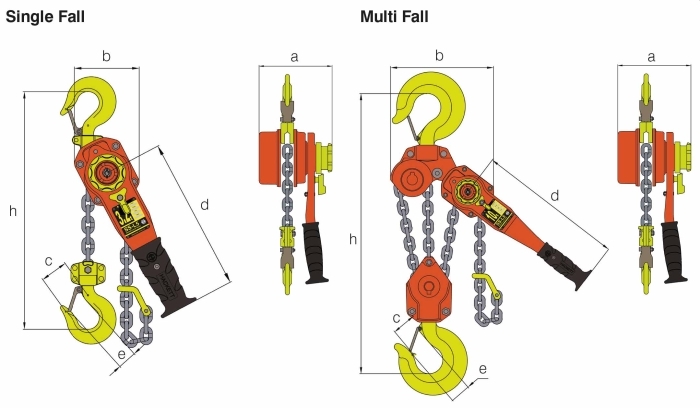

Specifications

|

Part Code |

WLL tonnes |

No. of Falls |

Load Chain mm |

Standard Lift m |

a mm | b mm | c mm | d mm | e mm | h mm | Nett Weight kg |

Extra Weight per M kg |

| 034.SS.080 | 0.80 | 1 | 5.6 x 15.7 | 3 | 146 | 119 | 42.0 | 245 | 27.0 | 280 | 5.85 | 0.70 |

| 034.SS.160 | 1.60 | 1 | 7.1 x 19.9 | 3 | 164 | 126 | 54.5 | 265 | 36.0 | 335 | 7.35 | 1.10 |

| 034.SS.320 | 3.20 | 1 | 10 x 28 | 3 | 196 | 159 | 60.5 | 415 | 42.0 | 395 |

13.70 |

2.20 |

| 034.SS.630 | 6.30 | 2 | 10 x 28 | 3 | 196 | 218 | 85.5 | 415 | 52.5 | 540 | 26.40 | 4.40 |

| 034.SS.1000 | 10.00 | 3 | 10 x 28 | 3 | 196 | 298 | - | 415 | 59.0 | 680 | 40.10 | 6.60 |

| 034.SS.1500 | 15.00 | 6 | 10 x 28 | 3 | 196 | 420 | - | 415 | 80.0 | 1000 | 70.20 | 13.20 |

| 034.SS.2000 | 20.00 | 8 | 10 x 28 | 3 | 196 | 480 | - | 415 | 80.0 | 1150 | 168.60 | 17.60 |