H-bar Adjustable lifting beams PALHR 1,000 kg to 10,000 kg - Dale Lifting - By Brand

H-bar Adjustable lifting beams PALHR 1,000 kg to 10,000 kg

Key Features

- For lifting of various loads up to 10 tonnes in spans from 1 to 4 metres

- Adjustment of hooks on secondary beams

- Equipped with 4 articulated, rotating hooks with forged safety latches

- Delivered with user's and maintenance manual and EC certificate of compliance

- Safety factor: 4

Delivery Information

Order online for delivery to Mainland UK VAT eligible locations only. Delivery charges will be shown in the shopping cart. Despatch dates for products can vary, if urgent, please contact us. Request a quote for postcodes DD, IV, KW, PA, AB, BT, HS, TR. PO30-PO42, southern Ireland, Channel Islands. For international destinations restrictions may apply.

Returns Policy

Simply email us at sales@dale-lifting.co.uk or call 0161 223 1990 and we will be able to give you a returns authorisation code, which must be sent with the returned item. Returns should be authorised within 14 days from the day of delivery to you. Items should be returned in unused condition & due to the nature of our products a restocking fee may apply. Unfortunately, delivery charges are not refundable. Items returned without an authorisation code may not be accepted. Normally All refunds will be processed within 7- 10 working days on receipt of returned goods.

Non-standard (Quote only, pre-order or custom-made products)

Custom made to order products are not covered by our returns policy. Please ensure when ordering all measurements and capacities are correct as we are unable to refund on these products.

For more information see https://www.dlhonline.co.uk/terms-conditions

PALHR- H-bar Adjustable lifting beams

Lifting of various loads up to 10 tonnes in spans from 1 to 4 metres

See important information below for correct loading

Description

- H-bar adjustable lifting beam

- Adjustment of hooks on secondary beams

- Adjustment of secondary beams on the main beam

- Equipped with 4 articulated, plain bearing swivel hooks with forged safety latches

- Tear-resistant eyelet for use with synthetic slings, cables, etc.

- Rust-proof paint + highly resistant RAL 1028 yellow polyurethane finish

- Safety factor: 4

- No structural weld

- Manufactured according to standard NFE 52210

- Group = FEM5

- Low headroom

- Maximum hoisting speed = 16m/min

- Delivered with user's and maintenance manual and EC certificate of compliance

- For superior capacities, contact us.

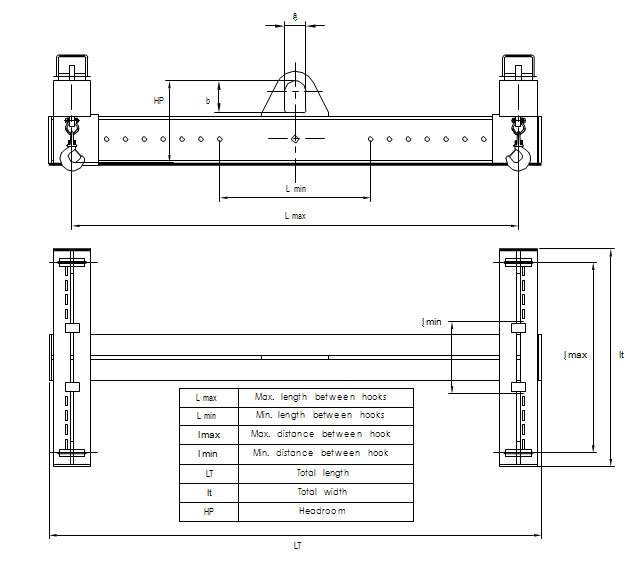

| Max. capacity | Max. length between hooks (L max) |

Min. length between hooks (L min) |

Max. distance between hook (l max) | Min. distance between hook (l min) | Total length (LT) | Overall dimension (lt) | Headroom (HP) | a | b | Weight |

| KG | mm | mm | mm | mm | mm | mm | mm | mm | mm | KG |

| 1 000 |

1 000 | 500 | 1 000 | 500 | 1 200 | 1 100 | 290 | 60 | 80 | 98 |

| 2 000 | 1 000 | 1 000 | 500 | 2 200 | 1 100 | 125 | ||||

| 3 000 | 1 000 | 1 000 | 500 | 3 200 | 1 100 | 162 | ||||

| 3 000 | 1 000 | 2 000 | 1 000 | 3 200 | 2 100 | 197 | ||||

| 4 000 | 2 000 | 1 000 | 500 | 4 200 | 1 100 | 188 | ||||

| 4 000 | 2 000 | 2 000 | 1 000 | 4 200 | 2 100 | 223 | ||||

| 2 000 |

1 000 | 500 | 1 000 | 500 | 1 200 | 1 100 | 320 | 80 | 120 | 105 |

| 2 000 | 1 000 | 1 000 | 500 | 2 200 | 1 100 | 138 | ||||

| 3 000 | 1 000 | 1 000 | 500 | 3 200 | 1 100 | 181 | ||||

| 3 000 | 1 000 | 2 000 | 1 000 | 3 200 | 2 100 | 231 | ||||

| 4 000 | 2 000 | 1 000 | 500 | 4 200 | 1 100 | 236 | ||||

| 4 000 | 2 000 | 2 000 | 1 000 | 4 200 | 2 100 | 286 | ||||

| 3 000 |

1 000 | 500 | 1 000 | 500 | 1 200 | 1 100 | 400 | 100 | 180 | 123 |

| 2 000 | 1 000 | 1 000 | 500 | 2 200 | 1 100 | 161 | ||||

| 3 000 | 1 000 | 1 000 | 500 | 3 200 | 1 100 | 230 | ||||

| 3 000 | 1 000 | 2 000 | 1 000 | 3 200 | 2 100 | 304 | ||||

| 4 000 | 2 000 | 1 000 | 500 | 4 200 | 1 100 | 301 | ||||

| 4 000 | 2 000 | 2 000 | 1 000 | 4 200 | 2 100 | 375 | ||||

| 4 000 |

1 000 | 500 | 1 000 | 500 | 1 200 | 1 100 | 400 | 100 | 180 | 147 |

| 2 000 | 1 000 | 1 000 | 500 | 2 200 | 1 100 | 197 | ||||

| 3 000 | 1 000 | 1 000 | 500 | 3 200 | 1 100 | 275 | ||||

| 3 000 | 1 000 | 2 000 | 1 000 | 3 200 | 2 100 | 341 | ||||

| 4 000 | 2 000 | 1 000 | 500 | 4 200 | 1 100 | 359 | ||||

| 4 000 | 2 000 | 2 000 | 1 000 | 4 200 | 2 100 | 425 | ||||

| 5 000 |

1 000 | 500 | 1 000 | 500 | 1 200 | 1 100 | 440 | 100 | 180 | 155 |

| 2 000 | 1 000 | 1 000 | 500 | 2 200 | 1 100 | 212 | ||||

| 3 000 | 1 000 | 1 000 | 500 | 3 200 | 1 100 | 302 | ||||

| 3 000 | 1 000 | 2 000 | 1 000 | 3 200 | 2 100 | 390 | ||||

| 4 000 | 2 000 | 1 000 | 500 | 4 200 | 1 100 | 392 | ||||

| 4 000 | 2 000 | 2 000 | 1 000 | 4 200 | 2 100 | 480 | ||||

| 6 000 |

1 000 | 500 | 1 000 | 500 | 1 200 | 1 100 | 440 | 100 | 180 | 178 |

| 2 000 | 1 000 | 1 000 | 500 | 2 200 | 1 100 | 249 | ||||

| 3 000 | 1 000 | 1 000 | 500 | 3 200 | 1 100 | 348 | ||||

| 3 000 | 1 000 | 2 000 | 1 000 | 3 200 | 2 100 | 424 | ||||

| 4 000 | 2 000 | 1 000 | 500 | 4 200 | 1 100 | 453 | ||||

| 4 000 | 2 000 | 2 000 | 1 000 | 4 200 | 2 100 | 550 | ||||

| 8 000 |

1 000 | 500 | 1 000 | 500 | 1 250 | 1 100 | 480 | 100 | 180 | 193 |

| 2 000 | 1 000 | 1 000 | 500 | 2 250 | 1 100 | 276 | ||||

| 3 000 | 1 000 | 1 000 | 500 | 3 250 | 1 100 | 388 | ||||

| 3 000 | 1 000 | 2 000 | 1 000 | 3 250 | 2 100 | 487 | ||||

| 4 000 | 2 000 | 1 000 | 500 | 4 250 | 1 100 | 531 | ||||

| 4 000 | 2 000 | 2 000 | 1 000 | 4 250 | 2 100 | 630 | ||||

| 10 000 |

1 000 | 500 | 1 000 | 500 | 1 250 | 1 100 | 480 | 100 | 180 | 219 |

| 2 000 | 1 000 | 1 000 | 500 | 2 250 | 1 100 | 310 | ||||

| 3 000 | 1 000 | 1 000 | 500 | 3 250 | 1 100 | 457 | ||||

| 3 000 | 1 000 | 2 000 | 1 000 | 3 250 | 2 100 | 531 | ||||

| 4 000 | 2 000 | 1 000 | 500 | 4 250 | 1 100 | 549 | ||||

| 4 000 | 2 000 | 2 000 | 1 000 | 4 250 | 2 100 | 673 |

Important Information

- Install necessary accessories on the lifting beam ensuring that these accessories meet all the lifting beam use conditions

- Attach the lifting beam to the lifting means

- Adjust both lower points -taking the load geometry into account- sliding them onto the profile.

- Securely position the adjustable attachment points between appropriate steel locking components.

- Hang the load on the lifting beam and perform lifting.

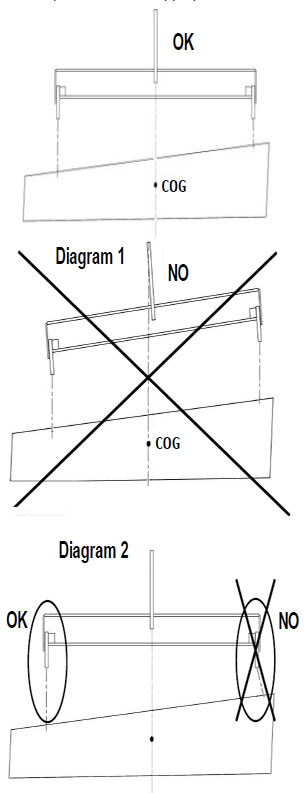

- Ensure that the load is evenly balanced: the lifting beam must be horizontal during lifting (see Diagram 1) and efforts on axle direction of lower points vertical (see Diagram 2).

- COG = Centre of gravity of the load

- Otherwise, stop the lifting and correctly position the load, the lifting beam and accessories.

Choice of accessories

Accessories like shackles, hooks, slings, etc. must be adapted to all lifting operations.

Important instructions

- Do not use for personnel lifting.

- Strictly forbidden to either be under or walk under the load

- Working temperature: -20° to +100°C.

- Accessories must be adapted to all lifting operation conditions.

- For all lifting operations, make sure that the load itself can withstand the bending stresses and deformations it is likely to be subjected to during the lifting operation.

- Never lift loads which have non-attached charges on top.

- Never exceed Working Load Limit of the equipment (W.L.L. – see engraving).

- The weight of the lifting beam, added to the weight of the load lifted, must be less than the capacity of the lifting appliance.

- Never mount more than one element in the hole of each lower point of the lifting beam.