RUD VLBS Load Ring With Spring For Welding - RUD Lifting Points Welded - RUD Lifting Points - By Brand

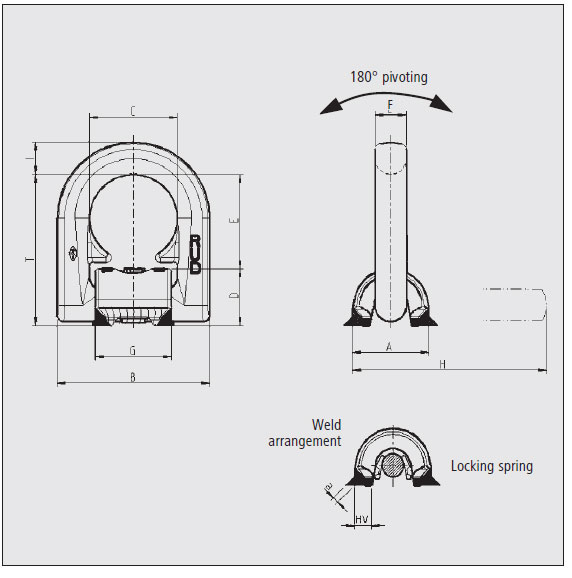

RUD VLBS Load Ring With Spring For Welding

Key Features

- Suspension ring pivots 180°

- Suspension ring & weld-on-block of the VLBS-U are undetachable

- Suspension ring can be angled into position (VLBS-U)

- Safety Factor 4:1

Delivery Information

Order online for delivery to Mainland UK VAT eligible locations only. Delivery charges will be shown in the shopping cart. Despatch dates for products can vary, if urgent, please contact us. Request a quote for postcodes DD, IV, KW, PA, AB, BT, HS, TR. PO30-PO42, southern Ireland, Channel Islands. For international destinations restrictions may apply.

Returns Policy

Simply email us at sales@dale-lifting.co.uk or call 0161 223 1990 and we will be able to give you a returns authorisation code, which must be sent with the returned item. Returns should be authorised within 14 days from the day of delivery to you. Items should be returned in unused condition & due to the nature of our products a restocking fee may apply. Unfortunately, delivery charges are not refundable. Items returned without an authorisation code may not be accepted. Normally All refunds will be processed within 7- 10 working days on receipt of returned goods.

Non-standard (Quote only, pre-order or custom-made products)

Custom made to order products are not covered by our returns policy. Please ensure when ordering all measurements and capacities are correct as we are unable to refund on these products.

For more information see https://www.dlhonline.co.uk/terms-conditions

RUD VLBS Load Ring With Spring For Welding

Complies with the machinery directives 2006/42/EG

| Type | WLL (t) |

A | B | C | D | E | F | G | H | I | T | Weld HV+ | Weight (kg) | Ref.-No. captive complete |

| VLBS 1.5 | 1.5 | 33 | 66 | 38 | 25 | 40 | 13.5 | 33 | 87 | 14 | 65 | HV 5 + 3 | 0.35 | 79 93 035 |

| VLBS 2.5 | 2.5 | 36 | 77 | 45 | 27 | 48 | 13.5 | 40 | 97 | 16 | 75 | HV 7 + 3 | 0.5 | 79 94 830 |

| VLBS 4 | 4 | 42 | 87 | 51 | 31 | 52 | 16.5 | 46 | 112 | 18 | 83 | HV 8 + 3 | 0.8 | 79 93 036 |

| VLBS 6.7 | 6.7 | 61 | 115 | 67 | 44 | 73 | 22.5 | 60 | 157 | 24 | 117 | HV 12 + 4 | 1.9 | 79 93 037 |

| VLBS 10 | 10 | 75 | 129 | 67 | 55 | 71 | 26.5 | 60 | 173 | 27 | 126 | HV 16 + 4 | 2.9 | 79 93 040 |

| VLBS 16 | 16 | 95 | 190 | 100 | 69 | 105 | 26 | 90 | 243 | 40 | 174 | HV 25 + 6 | 6.8 | 79 06 640 |

The VLBS forged out of high tensile CrNiMo - steel with an innovative design offers many advantages. - up to 50 % higher WLL.

- the two protective supporting lugs (inside the load ring) are patented and they improve the connection with the attachment, in addition, they protect the clamping spring.

- The support effect is exceptional, especially if the ring is side loaded or the lifting point is welded on an uneven workpiece.

- Pink powder coating, a VIP recognition attribute and a heat indicator (refer to page 15).

Easy and quick to weld assembly.

Compact and shapely design.

High dynamic and static strength.

Forged suspension ring ACC. to EN 1677, grade 80, electromagnetic crack detected, pink powder coated; meets the requirements of the appropriate safety authorities.

The welding block has been forged of material 1.0570 (St 52-3) and clearly stamped with the permissible WLL. The patented

distance lugs assist in achieving the correct root weld.

Important: By the special weld design (continuous HV), the requirements of DIN 18800 are fulfilled, i.e., a closed weld avoids corrosion and thus suitable for outdoor use.

Distinctive features for type LBS-U: A protected spring Maintains the load ring in every required position. The parts are assembled in such a way that they remain captive. The spring reduces vibration-induced noise.