Thern Spur Gear Lifting Winch M4312PBSS-CE - 907 Kg with brake (for lifting) – Stainless steel - Thern Hand Operated Winches - Thern - By Brand

Thern Spur Gear Lifting Winch M4312PBSS-CE - 907 Kg with brake (for lifting) – Stainless steel

Shipped direct from Manufacturer partner - Despatch generally 2 weeks - Prices ex works, for carriage and despatch request quotation to your address.

Key Features

- Machine Cut Spur Gears for accurate and long lasting service.

- Automatic Brake Models provide positive load control for lifting and lowering operations.

- Corrosion Resistant - Trivalent zinc plated finish protects against corrosion in harsh environments.

- Quick Disconnect Anchor for quickly attaching or removing wire rope equipped with a swaged ball fitting.

- Stainless stell construction

Delivery Information

Order online for delivery to Mainland UK VAT eligible locations only. Delivery charges will be shown in the shopping cart. Despatch dates for products can vary, if urgent, please contact us. Request a quote for postcodes DD, IV, KW, PA, AB, BT, HS, TR. PO30-PO42, southern Ireland, Channel Islands. For international destinations restrictions may apply.

Returns Policy

Simply email us at sales@dale-lifting.co.uk or call 0161 223 1990 and we will be able to give you a returns authorisation code, which must be sent with the returned item. Returns should be authorised within 14 days from the day of delivery to you. Items should be returned in unused condition & due to the nature of our products a restocking fee may apply. Unfortunately, delivery charges are not refundable. Items returned without an authorisation code may not be accepted. Normally All refunds will be processed within 7- 10 working days on receipt of returned goods.

Non-standard (Quote only, pre-order or custom-made products)

Custom made to order products are not covered by our returns policy. Please ensure when ordering all measurements and capacities are correct as we are unable to refund on these products.

For more information see https://www.dlhonline.co.uk/terms-conditions

Spur Gear Hand Winches

M4312PB-CE 907 Kg with brake (for lifting) –Stainless steel – double gear

Solid Steel Machine-Cut Gears

Precision-cut, zinc-coated steel gears resist corrosion, increase efficiency, and provide accurate and durable operation.

Adjustable handle can increase mechanical advantage or speed as load weight varies.

Welded Steel DrumRobust drum design and large spool diameter minimize drum wear and extend wire rope life.

Automatic Weston-Style Brake Spring-engaged, ratchet-pawl design offers additional reliability and positive load control for lifting and lowering. The Enclosed (pawl and ratchet) envelope keeps the brake clean, dry and protected for reliable service and haptic feedback. Durable friction discs reduce wear and increase service life.

Wire ropes are sold separately

Spur Gear Hand Winches Performance Characteristics — Metric |

||||||||||||

|

Load Rating kg |

Drum Capacity m2 |

|||||||||||

|

Model No. |

Description |

1st Layer |

Mid Drum |

Full Drum |

Wire Rope Dia.1 mm |

1st Laye mr |

Mid Drum m |

Full Drumm |

Sgl Gear Ratio |

Dbl Gear Ratio |

Force3 to Lift 453.5 kg |

Approx. Ship kg Wt. |

|

M4312PBSS |

907.1 kg — Stainless steel |

907.1 |

725.7 |

544.3 |

4.7 |

2.4 |

14.6 |

33.5 |

— |

14.7:1 |

7.7 |

12.7 |

|

with brake (for lifting) |

6.3 |

1.5 |

8.2 |

17.9 |

(dbl gear) |

|||||||

|

7.9 |

1.2 |

5.1 |

11.8 |

|||||||||

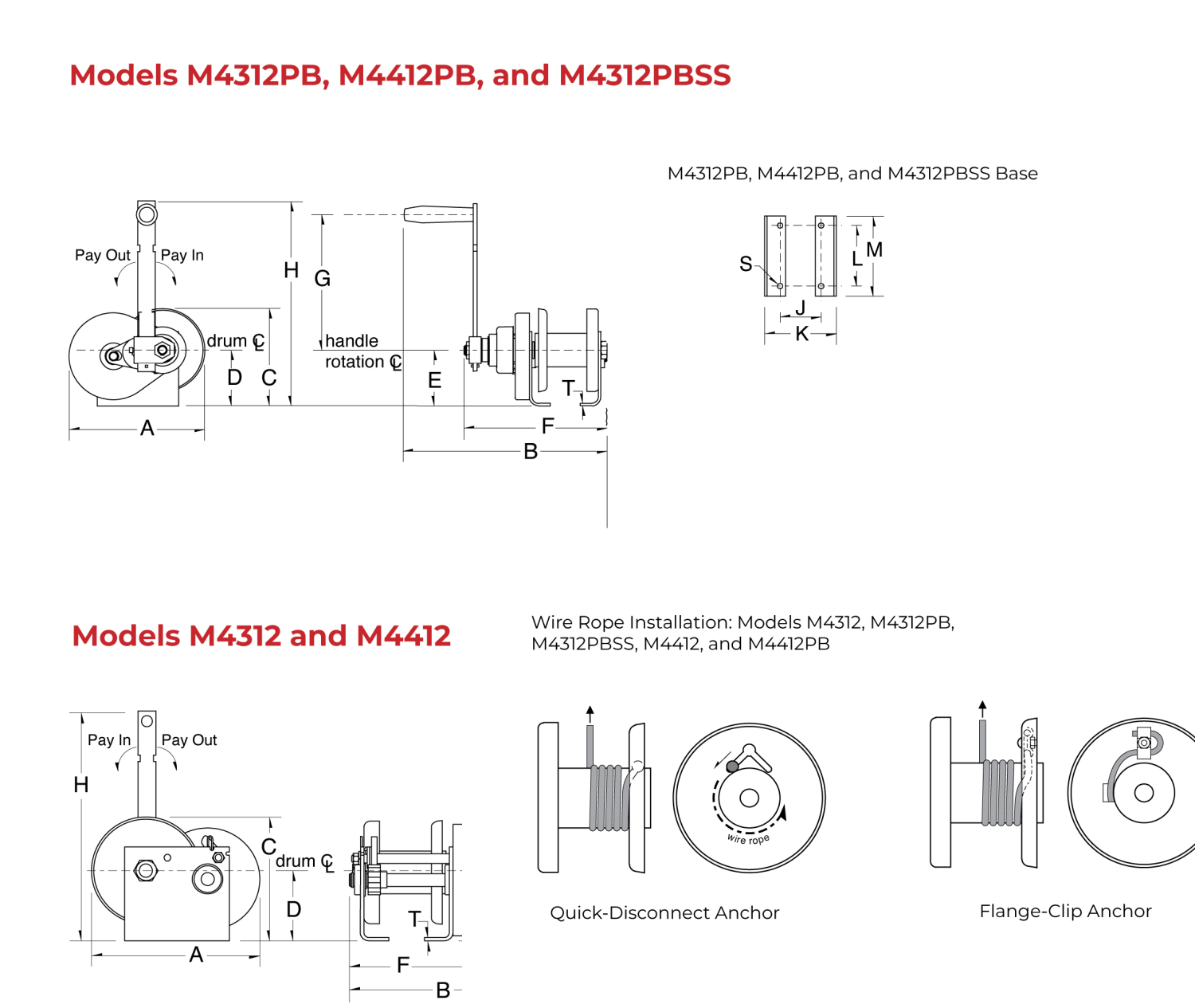

Spur Gear Hand Winches — Metric Dimensions |

|||||||||||||||||

|

Model No. |

Drum Dia. |

Flange Dia. |

Drum Width |

A |

B |

C |

D |

E |

F |

G1 |

H1 |

J |

K |

L |

M |

S (hole dia.) |

T |

|

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

|

|

M4312PBSS |

63.50 |

139.70 |

76.20 |

272.00 |

367.00 |

183.00 |

101.00 |

101.00 |

275.00 |

268.00 |

387.00 |

85.00 |

134.00 |

127.00 |

152.00 |

10.00 |

5.00 |

|

Dimensions are for reference only and are subject to change without notice. 1 Model M4312PB, handles are adjustable. Dimension shown is for the maximum handle length. |

|||||||||||||||||

IMPORTANT: It is the owner’s or operator’s responsibility to determine the suitability of the equipment to its intended use. Study all applicable codes, manuals and regulations. Be sure to read the Owner’s Manual supplied with the equipment before operating it.