Mezzbarriers Case Studies

Do your mezzanine openings meet the latest ISO standard for safety?

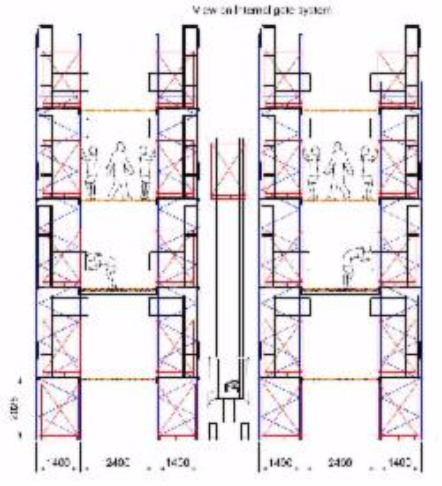

The latest BS EN ISO 14122-3:2016 standard requires that all platform openings over 500 mm higher than floor level MUST have a dual safety pallet gate system, to prevent personnel from falling through the unprotected opening.

Where do you need a dual pallet gate system?

To surround and protect any raised area being used for loading and unloading by forklift or hoist in the following locations:

● Mezzanine floors

● High-level hoist loading platforms

● Loading docks

● High-level openings

● High-level roller shutters

● High-level inward opening doors

● Bag or Sack handling process platforms

Read our case study for your application

Pallet gate for narrow platform outside a warehouse

Requirement: Pallet loading safety gate onto a narrow width loading platform for tall pallets access through warehouse opening with shared pedestrian access.

Read more...HSE Case study highlights need for Foolproof Fall Protection in Mezzanine Openings

Following a review of a risk assessment, an employer was concerned about the risk of falls from openings along the edge of a mezzanine floor when pallets were being placed and retrieved using a forklift truck.

Read more...Pallet loading Through Opening to 1st Floor Warehouse

Problems: Loading through an existing aperture in the floor with landing area intersected by through pallet truck access. Low headroom to existing light fitting. Confined space with through traffic.

Read more...Pallet Loading onto Upper-Level External Loading Platform

Problems: Loading 2.27 m high pallets through existing covered platform with headroom 2.32 m, Door frame at rear or platform 2.25 m high. external location

Read more...Pallet Gate in 1st. Floor Shutter Opening

Problems: Forklift loading access to 1st. floor maintenance shop through sliding shutter doorway. Shutter doorway with limited headroom and in an area with confined space.

Read more...Pallet Loading on to Narrow Walkway

Problems: Existing pallet loading access to the walkway were two swing-out gates in a narrow walkway barrier. Pallets with cardboard boxes up to 1850 mm high. As the walkway was less than the pallet depth the storeroom doors had to be open to obtain enough loading space. A risk assessment highlighted the danger of personnel, who were constantly using the walkway for access between offices

Loading Large Pallet Loads onto Mezzanine

Problems: Client had an existing fabricated steel pallet gate. Which, although seemed solidly built, it was very heavy to use and when opened the edge gate protruded over the edge. It was constantly being damaged by contact with the forklift mast. The stillage loads were very wide and high.

Read more...Loading Zone 2 Material Handling Cage on the Upper Floor

Pallet gate used in an opening with inward opening doors

Problems: Inward opening doors for pallet loading. Very low headroom due to external overhang and even less headroom inboard of doors with sloping beam and light fittings. Narrow ledge outboard of doors when closed made externally mounted gate impossible.

Pallet gate for use with vacuum handler

Problems: Loading through existing unguarded handrail aperture without adequate fall protection. Low headroom to clear crane arm. Confined workspace

Read more...

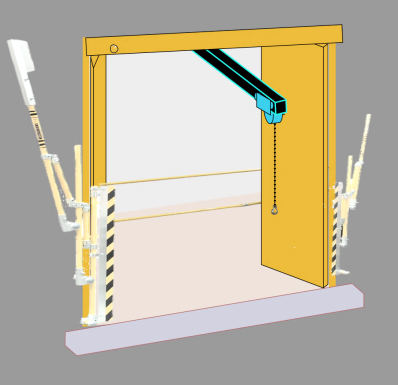

Safety Gate for Doorway with Hoist

Problem: High-level hoist doorways (Teagle openings) are particularly dangerous situations. Traditionally these have been provided with removal chains or bars across the opening and lately, the operator has been furnished with a safety harness. Safety professionals say these solutions are unsafe as even safety harnesses don't work as operators don't bother to wear the harness.

Read more...Pallet gate on ta wide loading dock

Problems: The loading dock roller shutter was close enough to the dock edge for a conventional up and over type gate. But was over 3.5 metres wide. The paint booth had to be moved back to accommodate the siting of the pallet gate.The gate had to be capable of accepting stacks of pallets 10 high, although the roller shutter had limited clearance. The roller shutter was routinely being left open between loading operations. This exposed any personnel to the danger of falling off the loading dock edge. Also during loading operations, personnel had additional hazard of coming into contact with moving loads.

Read more...Pallet Gate for Order Picking Racking System

Problems: Narrow aisles make the use of a standard up and over gates a collision hazard to forklift traffic. Low height racking with high load pallets. Pallet gates being used by all picking personnel.

Pallet Gate for Corner Loading Platform

Problems: The loading platform was quite small and had double opening doors to a cleanroom tight up to the side of the loading edge. The pallets were to be loaded onto a pallet truck from the side and pulled back into the cleanroom. It was impossible to use a standard up and over type pallet gate.

Read more...Extra Wide Pallet Gate for Mezzanine Floor

Problems: To load large weldmesh panels and products onto a mezzanine floor. Provide custom pallet gate to extend the full width of mezzanine and take full advantage of available headroom.

Read more...Pallet Gate for Roller Shutter Opening

Problem: Gate normally positioned behind roller shutter. This invariably means the gate is some distance from the edge

Read more...